Description

This 214 page, Ford New Holland L35 L775 L778 And L779 Skid Steer Service Manual is a reproduction of the original out of print manual. This book provides in condensed form, service and maintenance information which will serve to guide a serviceman when repairing or rebuilding Sperry New Holland L-35, L-775, L-778 or L-779 skid-steer loaders in the shop and to help him when diagnosing and correcting service difficulties in the field. The operator’s manuals and assembly information provided with each machine should be used in conjunction with this manual, as much of the information contained in this manual Is condensed or supplementary in nature. For instructions on engine repair, refer to the manufacturer’s repair manual.

Ford New Holland L35 L775 L778 And L779 Skid Steer Service Manual Model Coverage

Sperry New Holland L-35 skid-steer loaders

Sperry New Holland L-775 skid-steer loaders

Sperry New Holland L-778 skid-steer loaders

Sperry New Holland L-779 skid-steer loaders

Table of Contents

Foreword

Safety

Introduction

Servicing Vickers-equipped Loaders

Section 1 – Vickers Transmission Removal

Section 2 – Hydrostatic Transmission Operation

Section 3 – Vickers Transmission Disassembly

Section 4 – Vickers Transmission Pump And Motor Shimming

Section 5 – Shimming Procedure For Vickers Four-way Gear Box

Section 6 – Vickers Steering Control Adjustments

Section 7 – Vickers Vane Pump Removal, Inspection And Installation

Section 8 – Proportional Flow Divider

Section 9 – Steering Cylinder Rebuilding

Servicing Cessna-equipped Loaders

General Information

Section 1 – Cessna Transmission Removal

Section 2 – Cessna Transmission Overhaul

Section 3 – Cessna Transmission Oil Leaks

Section 4 – Shimming Four-way Gear Box

Section 5 – System Cleaning Procedure After Transmission Overhaul

Section 6 – Hydraulic Reservoir And Check Valve Assembly

Section 7 – Steering Neutralizer Repair

Section 8 – Cessna Steering Control Adjustments

Section 9- Cessna Gear Pump Removal, Inspection And Installation

General Information Vickers And Cessna-equipped Skid-steer Loaders

Section 1 – Start-up Procedure

Section 2 – Final Drive Disassembly And Assembly

Section 3 – Hydraulic System Pressure Checks

Section 4 – Servicing The Control Valve

Section 5 – Rebuilding Bucket And Boom Cylinders

Section 6-electrical System

Section 7- Boom Lockout

Section 8 – Fuel Tank Removal

Section 9 – Specifications – L-35 Loader, L-775 Loader, L-778 Loader, L-779 Loader

Section 10 – Hydraulic Circuit Diagrams

Section 11 – Trouble Shooting

Section 12-torque Charts

Adjustable Fittings

Bite-type Flareless Fittings

Tube Fitting Trouble Shooting

Index

Index of Topics

CONTENTS

FOREWORD

GENERAL IN FORM ATI ON-VICKERS & CESSNA

EQUIPPED SKID-STEER LOADERS

BOOM LOCKOUT

Seat activated boom lockout – Style I

Seat activated boom lockout – Style II

Servicing the boom lockout

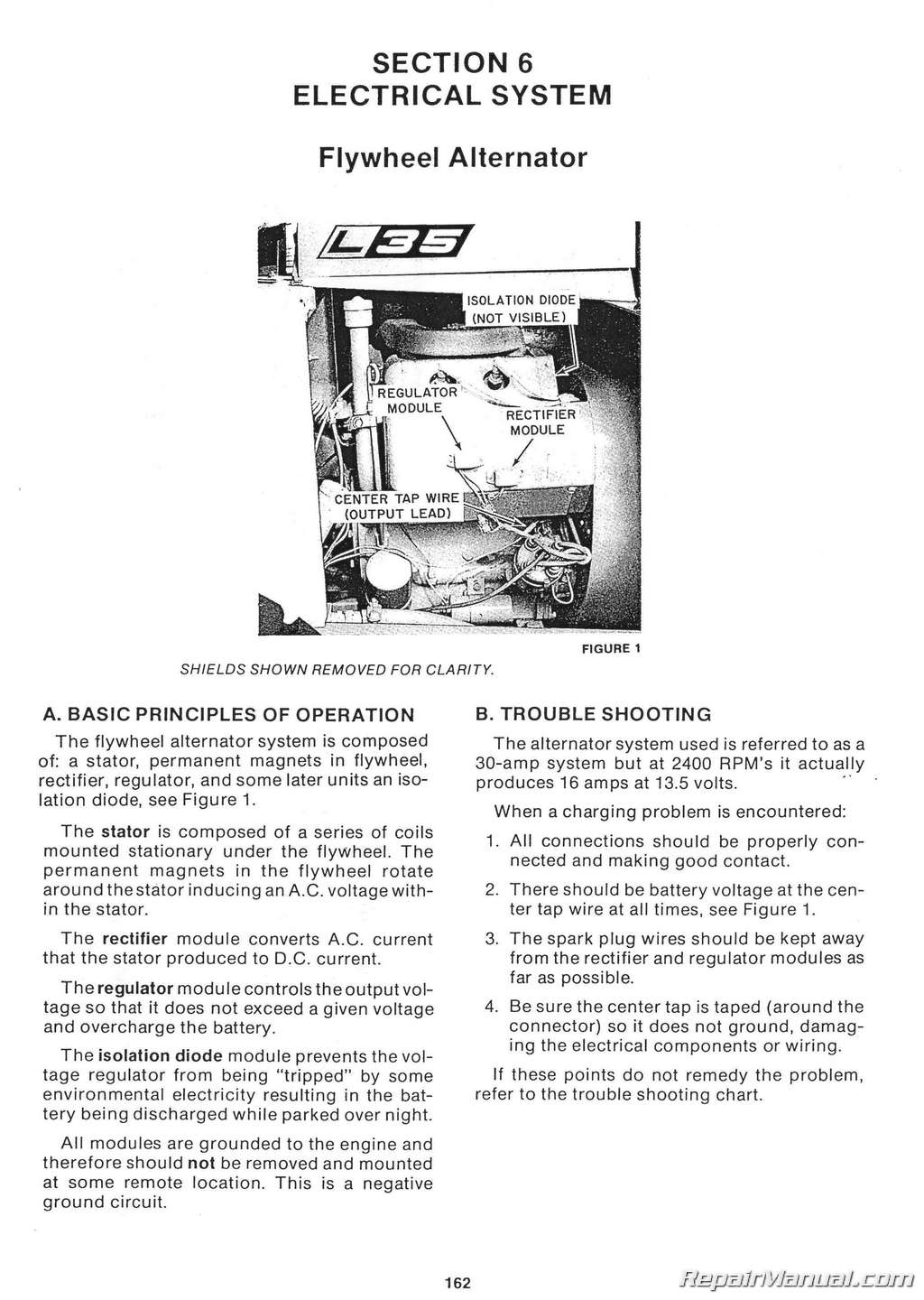

ELECTRICAL SYSTEM

Alternator test – RA series

Alternator test – TA series

Basic principles of operation-flywheel

alternator

Motorola exterior alternator

Troubleshooting

FINAL DRIVE DISASSEMBLY AND ASSEMBLY

Additional information

Disassembly

Reassembly

FITTINGS

Adjustable

Bite-type flareless

Trouble shooting

FUEL TANK REMOVAL

HYDRAULIC CIRCUIT DIAGRAMS

L-35 – Cessna Transmissions

L-35 – Vickers Transmissions

L-775 – Cessna Transmissions

L-775 – Vickers Transmissions

L-778 Cessna Transmissions

L-779 Cessna Transmissions

HYDRAULIC SYSTEM PRESSURE CHECKS____

Checking the main system pressure

Hydraulic system

Main system relief valve

Transmission system

REBUILDING BUCKET AND BOOM CYLINDERS

Boom cylinders-double acting

Boom cylinders-single acting

Bucket tilt cylinder :

Identification

REPAIR OPERATIONS-AVERAGE TIME

SERVICING THE CONTROL VALVE

Lift check valves

Main system relief valve

Spools and O-rings

SPECIFICATIONS

L-35

L-775

L-778

L-779

START-UP PROCEDURE

Cessna-equipped loaders

Vickers-equipped loaders

TORQUE CHARTS

TROUBLE SHOOTING

Cessna

Hydraulic pumps

Vickers

INTRODUCTION

SAFETY

SERVICING CESSNA-EQUIPPED LOADERS

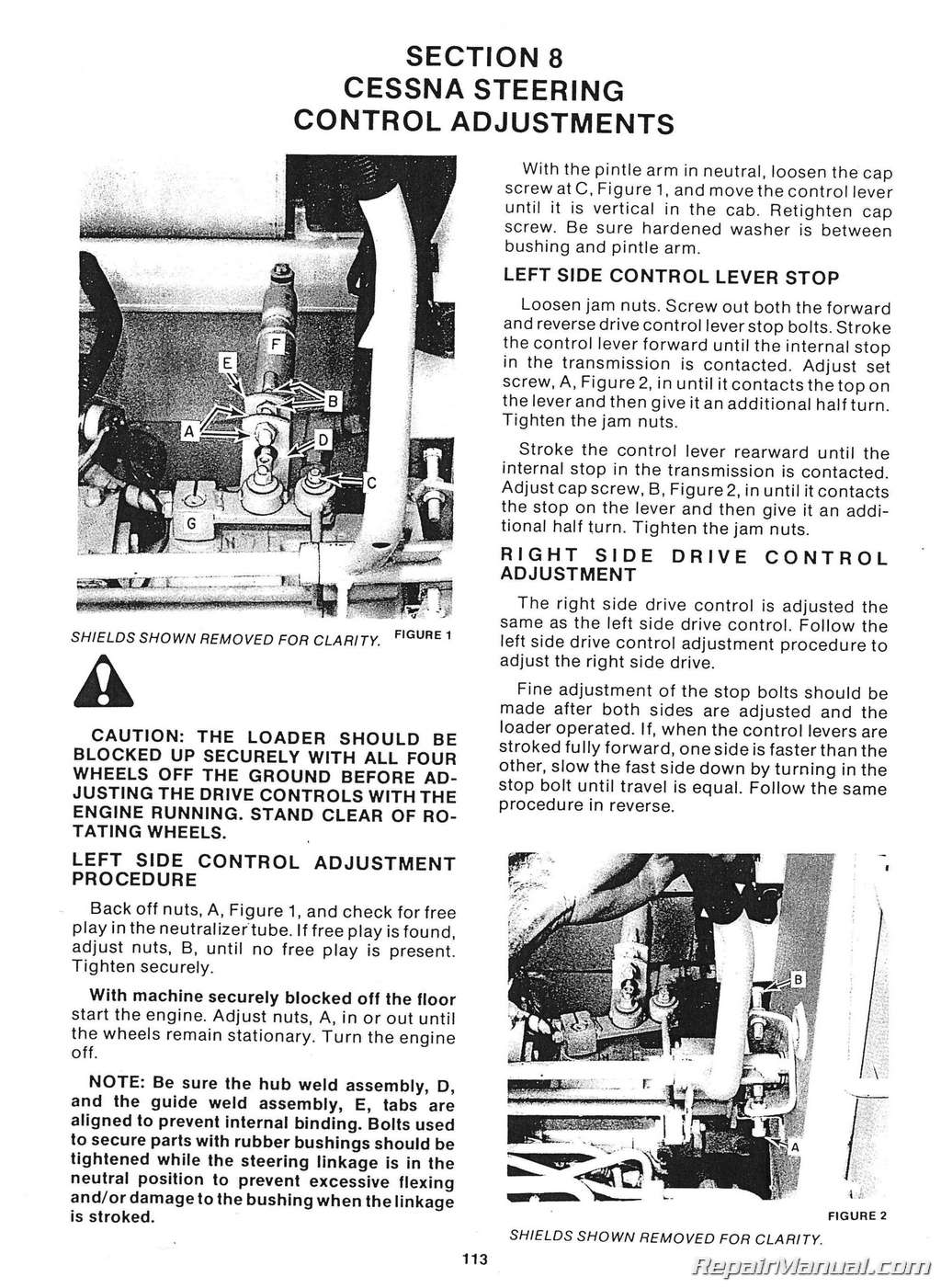

CESSNA STEERING CONTROL ADJUSTMENTS

High and low range control adjustment

Left side control adjustment procedure

Left side control lever stop

Right side drive control adjustment

CESSNA TANDEM GEAR PUMP REMOVAL

INSPECTION AND INSTALLATION

Inspecting and rebuilding the gear pump

Removing the gear pump

CESSNA TRANSMISSION REMOVAL

CESSNA TRANSMISSION OVERHAUL

Disassembly

Inspection and identification of parts

Reassembly

Winching valve

CESSNA TRANSMISSION OIL LEAKS

Gasket leaks

Pintle shaft leaks

Shuttle valve plug leak

GENERAL INFORMATION

HYDRAULIC RESERVOIR AND CHECK VALVE

ASSEMBLY

Cessna hydraulic systems

SHIMMING FOUR-WAY GEARBOX

Additional information

Drive shaft guard

Drive shaft installation

Rebuilding four-way gearbox in the loader

STEERING NEUTRALIZER REPAIR

SYSTEM CLEANING-PROCEDURE AFTER TRANSMISSION OVERHAUL

SERVICING VICKERS-EQUIPPED LOADERS

HYDRAULIC SCHEMATIC – L-35 AND L-775

PROPORTIONAL FLOW DIVIDER

Disassembly of the flow divider

Inspection and assembly

SHIMMING PROCEDURE FOR VICKERS

FOUR-WAY GEARBOX

Pre-load input shaft

Shimming transmissions to gearbox

STEERING CYLINDER REBUILDING

Disassembly

Inspection•

Reassembly

VICKERS HYDROSTATIC OPERATION

VICKERS STEERING CONTROL ADJUSTMENTS

Centering spring assembly

High and low range control adjustment

Left side drive control adjustment procedure

Left side drive control lever stop

Right side drive control adjustment

VICKERS TRANSMISSION REMOVAL

VICKERS TRANSMISSION DISASSEMBLY

Assembly

Disassembly of hydrostatic motor

Inspection and repair

Pump and motor

VICKERS TRANSMISSION PUMP AND MOTOR

SHIMMING

Assembly

Motor

Shimming procedure

Pump

VICKERS VANE PUMP INSPECTION, REMOVAL

AND INSTALLATION

Determining extent of pump problem

Pump installation

Rebuilding the vane pump

Removing vane pump

SKU: JS-FO-O-231

SKU: JS-FO-O-231 SKU: JS-FO-S-KNOTTERS

SKU: JS-FO-S-KNOTTERS SKU: JS-FO-S-2N-8N-9N

SKU: JS-FO-S-2N-8N-9N