Description

This 167 page, 1964-1967 Hodaka Ace 90 Service Manual is a reproduction of the original, out of print manual. This manual provides detailed service information, step-by-step repair instruction and maintenance specifications for 1964-1967 Hodaka Ace 90 motorcycles. The Hodaka Industrial Co. Ltd. has been building engines and transmissions for the motorcycle industry for many years. From 1951 to 1963 they produced engines in displacements ranging from 50cc to 500cc, including 500cc professional racing engines. In 1963, Pacific Basin Trading Company designed a complete motorcycle for Hodaka to manufacture for the American market. The keynote feature of Hodaka design was ease of maintenance and repair procedures. The Hodaka motorcycle is simplicity personified, requiring but a minimum of special tools and man hours to complete normal repairs. In order to assist the owner or mechanic to complete necessary maintenance and/or repairs, PABATCO has compiled this workshop manual. A thorough study of this text prior to beginning work will effect a considerable saving in time and, possibly, money. This workshop manual is dedicated to keeping Hodaka performance at factory-new standards.

1964-1967 Hodaka Ace 90 Service Manual Coverage: 1964, 1965, 1966, 1967 Hodaka Ace 90 motorcycles

1964-1967 Hodaka Ace 90 Service Manual Table of Contents

Introduction

Foreword

Table Of Contents

Table Of Illustrations

I Modification History

Ii Two Strokes Basic Principles

Iii General Maintenance

Iv Brakes /

1 Adjusting The Front Brake

2 Adjusting The Rear Brake

3 Adjusting The Brake Cam Levers

4 Adjusting The Stoplight Switch

5 Lubrication

6 Brake Drum And Shoe Service

A Removing The Rear Wheel

B Removing The Front Wheel

C Disassembling Backing Plate Assembly

D Cleaning And Inspecting Brake Components

E Reassembling The Backing Plate Components

F Remounting The Rear Wheel

G Remounting The Front Wheel

V Chain

1 Drive Chain: Minor Adjustment

2 Drive Chain: Major Adjustment

3 Adjusting The Chain Guide

4 Lubrication

5 Removing And/or Replacing Master Links

6 Service

Vi Clutch

1 Clutch Cable Adjustment

2 Clutch Lever Adjustment

3 Lubrication

A Clutch Cable Assembly

B Clutch Assembly

4 Clutch Service

A Removing Clutch Assembly

B Removing Clutch Lever From Side Cover

C Disassembling Clutch Assembly

D Cleaning And Inspecting Clutch Components

E Reassembling Clutch Assembly

F Reassembling Side Cover Assembly

G Remounting Clutch And Side Cover Assemblies

Vii Magneto / Alternator Assembly

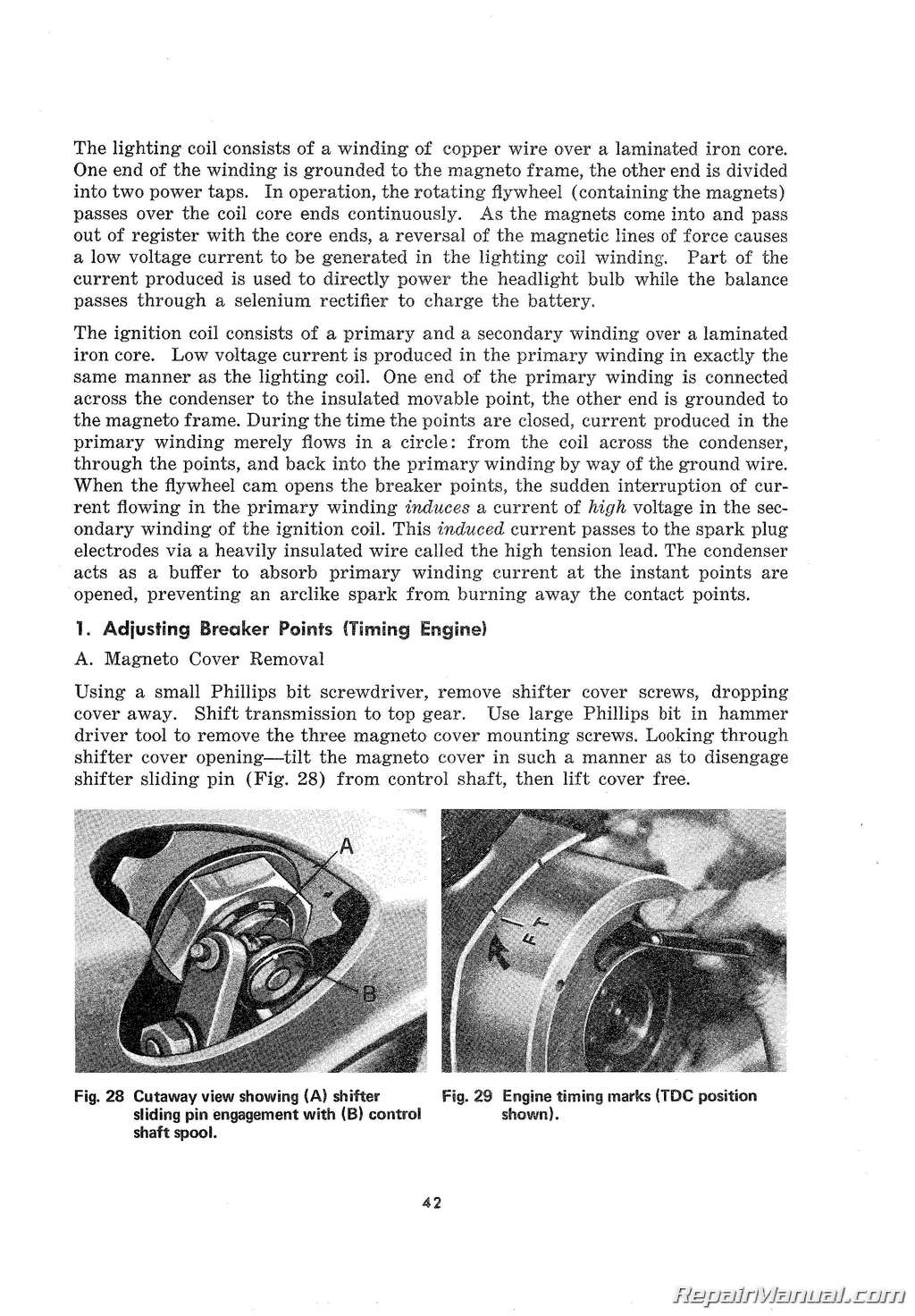

1 Adjusting Breaker Points (timing Engine)

A Magneto Cover Removal

B Timing The Engine By Gap Setting Method

C Alternative Timing Methods

2 Lubrication

3 Tests And Checks

4 Magneto/alternator Service

A Flywheel Removal

B Magneto Frame Assembly Removal

C Disassembling Magneto Frame Components

D Cleaning And Inspecting Magneto Components

E Reassembling Magneto Frame Assembly

F Remounting Magneto Frame Assembly

G Remounting Flywheel And Magneto Cover

Viii Cylinder And Piston

1 Cylinder And Piston Service

A Cylinder Head And Cylinder Removal

B Piston Removal

C Cleaning, Inspecting, Measuring, And Fitting Operations

D Reassembling Piston Onto Connecting Rod

E Remounting Cylinder And Cylinder Head

Ix Engine Case Assembly

1 Adjusting Transmission Gear Selector System

A Trial-and-error Method

B Measurement Method

2 Lubrication •

A Engine Assembly

B Transmission Assembly

C Magneto Cover Shifter Mechanism

3 Crankcase, Crankshaft, Transmission And

Kick Starter Service

A Removing Engine Assembly From Frame

B Dismantling Engine Case Assembly

C Cleaning And Inspecting Engine Case Components

D Reassembling Crankshaft Assembly

E Reassembling Engine Case Assembly

4 Magneto Cover Shifter Assembly Service

A Disassembling Magneto Cover Assembly

B Cleaning And Inspecting For Wear

C Reassembling Magneto Cover Assembly

X Electrical System

1 Headlight Assembly

A Adjusting Headlight Beam Position

B Tests And Checks

C Service

2 Tail And Stoplight Assembly

A Tests And Checks

B Taillight Service

3 Horn

A Adjusting The Horn

B Tests And Checks

4 Main Switch

5 Wiring Diagram

6 Dimmer Switch

7 Battery

A To Prepare A New Battery For Service

B Maintenance

8 Stoplight Switch

A Maintenance

9 Fuse

10 Selenium Rectifier

A Selenium Rectifier Test

11 Spark Plug

A Heat Ranges

B Numbering System For Heat Range

C Length (reach)

D Electrode Gap

E Cleaning

F Installation

G Various Aspects Of Firing Ends

H Normal Operation

I Oil Fouled

J Carbon Fouled

K Overheating

L Whiskering

Xi Fuel System

1 Carburetor

A Starting Circuit

B Idle To Intermediate Speed Circuit

C Intermediate To High Speed Circuit

D Mixture Adjustments

E Engine Idle Speed Adjustment

F Float Level Adjustment

G Carburetor Service

2 Manifold Assembly

A Service

3 Fuel Tank Assembly

A Service

4 Fuel Cocks

A Service

5 Fuel Lines

A Service

6 Throttle Cable Assembly

A Adjustment

B Lubrication

C Service

7 Twistgrip Assembly

A Lubrication

B Service

8 Air Cleaner Assembly

A Cleaning And Lubrication

B Service

Xii Exhaust System

1 Service Frequency

2 Spark Arrester Conversion

3 Exhaust System Service

A Removing Exhaust System

B Dismantling Exhaust System

C Cleaning And Inspecting Exhaust Components

D Reassembling And Remounting Exhaust System

Xiii Frame And Suspension Components

1 Frame

A Service

2 Steering Head Bearing Assembly

A Adjusting Steering Head Bearing Play

B Lubrication

C Steering Head Bearing Service

3 Front Fork And Handlebar Assembly

A Front Fork Alignment

B Lubrication

C Fork Service

4 Rear Fork Assembly (rear Suspension)

A Service

5 Fenders And Braces

A Service

6 The Saddle (seat)

A Service

7 Brake Pedal Assembly

A Service

8 Footrest Assembly

A Service

9 Battery Bracket

A Service

10 Side Stand

11 Tool Box Assembly

12 Carrier Rack

Xiv Wheels

1 Tires

A Tire Pressure

B Inspection

C Repairing Flats

2 Wheels

A Inspection

B Lubrication

C Wheel Bearing Service

D Truing Wheels

E Lacing Wheels

F Balancing Wheels

Supplemental Specifications

Engine

Carburetor

Magneto/alternator

Clutch

Primary Drive

Transmission

Final Drive

Kick Starter

Lighting System Equipment

Frame

Front Suspension

Rear Suspension

Wheel Rims

Tires & Tubes

Brakes

Dimensions & Weight

Torque Settings

Capacities

Clearances

Compression Pressure

Performance

Timing Specifications

Ace 90 Ignition Timing

Ace 90 Transfer Port Timing

Ace 90 Exhaust Port Timing

Ace 90 Inlet Port Timing

Ace 90 Stock Engine Port Timing Diagram Conversion Table/gallon To Quart To Pint To Liter

Metric Equivalents

Length

Area

Volume

Capacity

Weight

Pressure

Conversion Factors

Conversion Chart – Cubic Inches To Cubic Centimeters

Approximate Weight Of Various Liquids

Approximate Weight Of Various Materials

Conversion Chart/fraction Inch To

Decimal Inch To Mm

Dimensions Of Popular Ball Bearings

Drill Sizes

Conversion Chart: Tire Pressures

Conversion Chart: Temperature

Hodaka Workshop Tools

Handy Formulas

Ngk Spark Plug Conversion Chart

Racing Spark Plugs

Air And Fuel Proportioning Table

1964-1967 Hodaka Ace 90 Service Manual Table of Illustrations

Piston and cylinder view

Cutaway drawing, Hodaka two-stroke engine

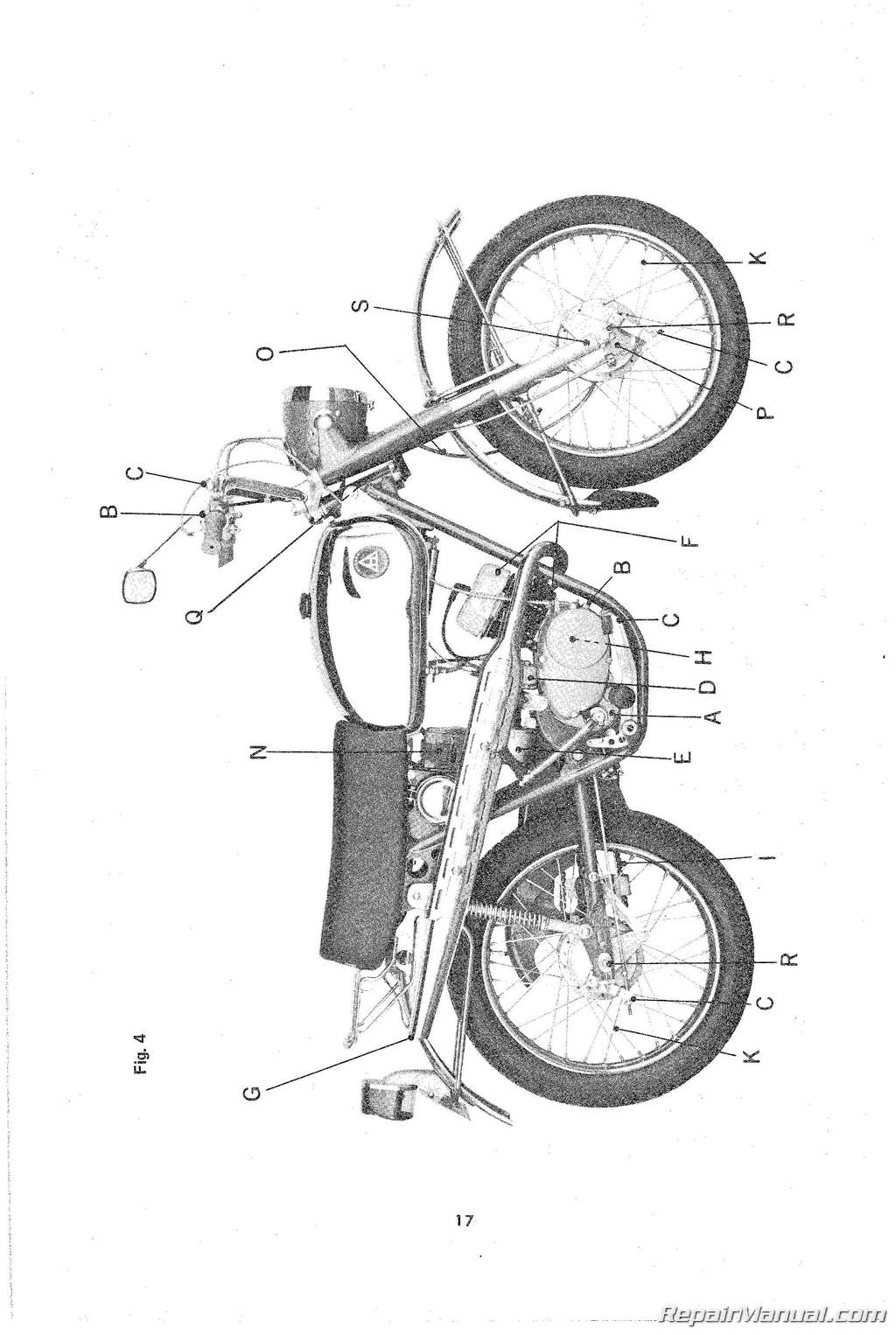

Side view of motorcycle

Front and rear brake components

Cable adjuster and brake lever details

Front brake cable slack adjustment

Rear brake adjustment

Stoplight switch

Loosening pinch bolt—front axle

Lubricating brake cam shaft

Rear axle assembly

Chain, chain guard and chain guide

Master link

Chain adjuster

Chain slack and chain guide clearance setting

Removing clip from master link

Measuring chain wear

Cross section of clutch assembly

Clutch lever free play

Clutch cable and lever details

Kickstarter lever hold-down technique

Transmission drain plug location

Removing clutch side cover

Removing clutch disc and spacers

Clutch holding tool in position

Clutch assembly

Pinion bushing position

Magneto/alternator components

Shifter sliding pin engagement

Engine timing marks

Breaker gap setting

Magneto frame assembly

Removing flywheel nut

Using flywheel puller to remove flywheel

Flywheel details

Cylinder assembly

Removing cylinder

Removing piston pin snap rings

Withdrawing piston pin

Piston ring side clearance measurements

Piston to cylinder clearance

Squaring piston ring in cylinder

Measuring piston ring end gap

Piston ring end gap measurements

Installing piston onto connecting rod

Installing cylinder base gasket

Installing cylinder

Tightening cylinder head nuts

Magneto cover assembly

Crankcase assembly

Crankshaft assembly

Transmission and kick starter assembly

Shift mechanism details

Control shaft details

Cross section of transmission

Cross section of kick starter drive mechanism

Shifter cover opening

Shifter arm adjustment measurements

Transmission drain plug

Removing nut securing primary gear

Removing counter shaft sprocket nut

Removing shaft collar from counter shaft

Method of separating crankcase halves

Depressing control shaft spring stopper

Heating bearing bosses

Method of extracting mainshaft bushing

Crankcase oil passage and transmission breather

Crankshaft, measurements and clearances

Components assembled into right case

Applying sealer to crankcase

Installation pattern for crankcase screws

Installing kick spring

Headlight assembly

Electrical system components

Cross-section view of horn

Main switch positions

Hodaka ACE 90 wiring diagram

Method of ballasting trickle charger circuit

Selenium rectifier test

Spark plug details

Normal plug condition

Oil-fouled plug

Carbon-fouled plug

Overheated plug condition

Whiskered plug condition

Carburetor starting circuit

Carburetor idle to intermediate speed circuit

Carburetor intermediate to high speed circuit

Removing main jet

Throttle adjuster

Adjusting idle with air screw

Throttle valve cutaway

Jet needle

Float height measurement

Method of adjusting float height

A Fuel system components

Exhaust system

Details of frame, steering head bearing assembly, front fork assembly and handlebars

Loosening steering head nut

Adjusting steering head bearing play

Lubricating lower steering head bearing

Removing handlebar holder

Using “C” spanners to remove inside nut

Supporting fork assembly when removing or replacing

View showing ball bearings packed into bearing race

Front fork details

Measuring oil level in front fork

Dismantled fork assembly

Using tool to pull inner tube into position

Rear fork assembly

Method of releasing saddle cover clips

Stretching new cover over saddle

Brake pedal assembly

Footrest assembly

Battery bracket assembly

Side stand

Tool box assembly

Detail of A and B spokes

Installing first “A” spoke

Installing “A” spokes into rim

Installing second set of “A” spokes

Installing first “B” spoke

Installing final set of “B” spokes

ACE 90 port timing diagram

Shop tools