Description

This Allis Chalmers 180 and 185 Service Manual is a reproduction of the original out of print manual It provides detailed service information, step-by-step repair instruction and maintenance specifications for Allis Chalmers 180 and 185 tractors.

Allis Chalmers 180 and 185 with serial # (1001-1596)

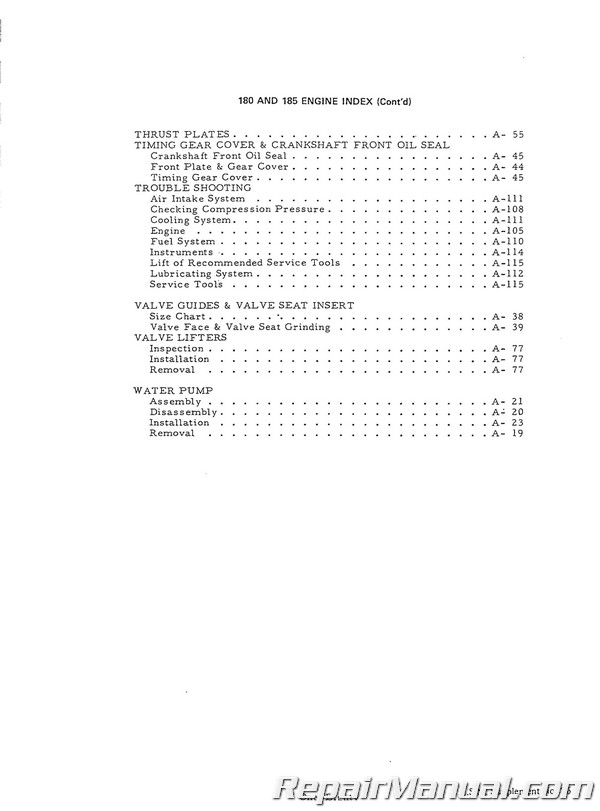

Table of Contents

DIESEL ENGINE

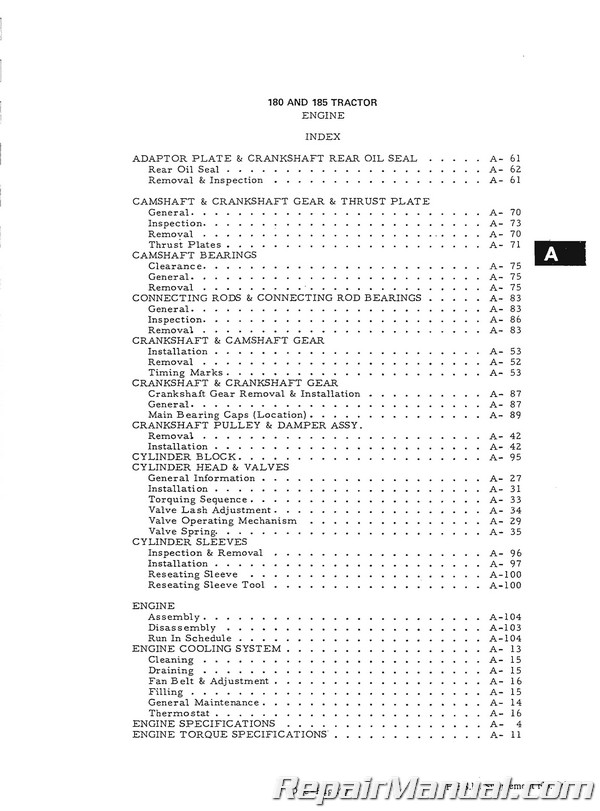

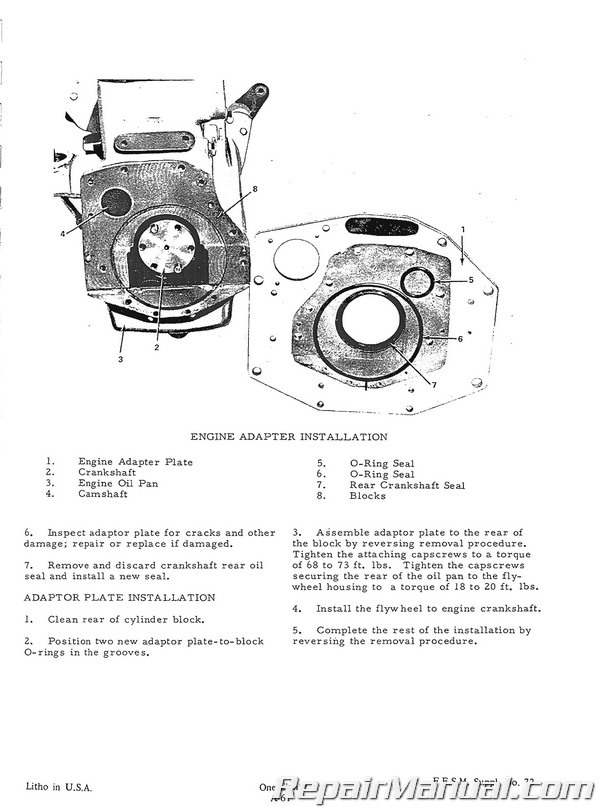

ADAPTOR PLATE & CRANKSHAFT REAR OIL SEAL

Rear Oil Seal

Removal & Inspection

CAMSHAFT & CRANKSHAFT GEAR & THRUST PLATE

General

Inspection

Removal

Thrust Plates

CAMSHAFT BEARINGS

Clearance

General

Removal

CONNECTING RODS & CONNECTING ROD BEARINGS

General

Inspection

Removal

CRANKSHAFT & CAMSHAFT GEAR

Installation

Removal

Timing Marks

CRANKSHAFT & CRANKSHAFT GEAR

Crankshaft Gear Removal & Installation

General

Main Bearing Caps (Location)

CRANKSHAFT PULLEY & DAMPER ASSY

Removal

Installation

CYLINDER BLOCK

CYLINDER HEAD & VALVES

General Information

Installation

Torqueing Sequence

Valve Lash Adjustment

Valve Operating Mechanism

Valve Spring

CYLINDER SLEEVES

Inspection & Removal

Installation

Reseating Sleeve

Reseating Sleeve Tool

ENGINE

Assembly

Disassembly

Run In Schedule

ENGINE COOLING SYSTEM

Cleaning

Draining

Fan Belt & Adjustment

Filling

General Maintenance

Thermostat

ENGINE SPECIFICATIONS

ENGINE TORQUE SPECIFICATIONS

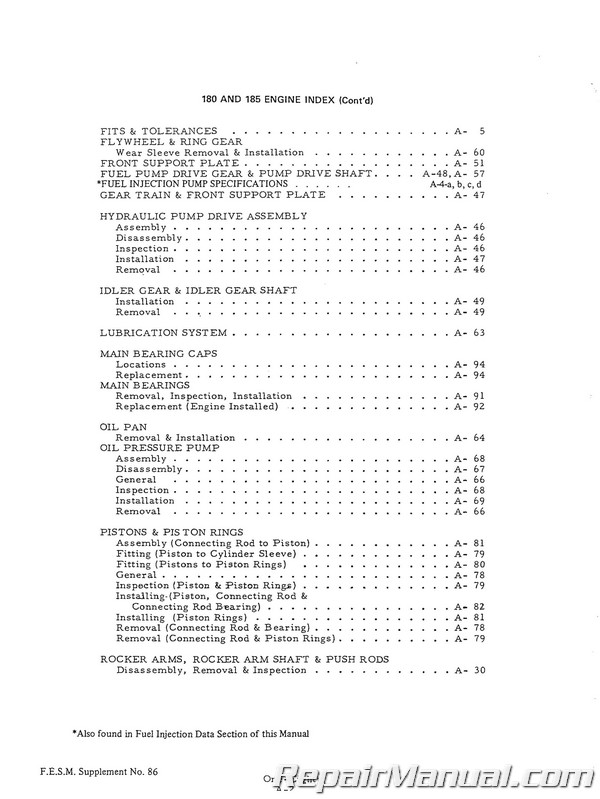

FITS & TOLERANCES

FLYWHEEL & RING GEAR

Wear Sleeve Removal & Installation

FRONT SUPPORT PLATE

FUEL PUMP DRIVE GEAR & PUMP DRIVE SHAFT

FUEL INJECTION PUMP SPECIFICATIONS

GEAR TRAIN & FRONT SUPPORT PLATE

HYDRAULIC PUMP DRIVE ASSEMBLY

Assembly

Disassembly

Inspection

Installation

Removal

IDLER GEAR & IDLER GEAR SHAFT

Installation

Removal

LUBRICATION SYSTEM

MAIN BEARING CAPS

Locations

Replacement

MAIN BEARINGS

Removal, Inspection, Installation

Replacement (Engine Installed)

OIL PAN

Removal & Installation

OIL PRESSURE PUMP

Assembly

Disassembly

General

Inspection

Installation

Removal

PISTONS & PISTON RINGS

Assembly (Connecting Rod to Piston)

Fitting (Piston to Cylinder Sleeve)

Fitting (Pistons to Piston Rings)

General

Inspection (Piston & Piston Rings)

Installing-(Piston, Connecting Rod &

Connecting Rod Bearing)

Installing (Piston Rings)

Removal (Connecting Rod & Bearing)

Removal (Connecting Rod & Piston Rings)

ROCKER ARMS, ROCKER ARM SHAFT & PUSH RODS

Disassembly, Removal & Inspection

THRUST PLATES

TIMING GEAR COVER & CRANKSHAFT FRONT OIL SEAL

Crankshaft Front Oil Seal

Front Plate & Gear Cover

Timing Gear Cover

TROUBLE SHOOTING

Air Intake System

Checking Compression Pressure

Cooling System

Engine

Fuel System

Instruments

Lift of Recommended Service Tools

Lubricating System

Service Tools

VALVE GUIDES & VALVE SEAT INSERT

Size Chart’

Valve Face & Valve Seat Grinding

VALVE LIFTERS

Inspection

Installation

Removal

WATER PUMP

Assembly

Disassembly

Installation

Removal

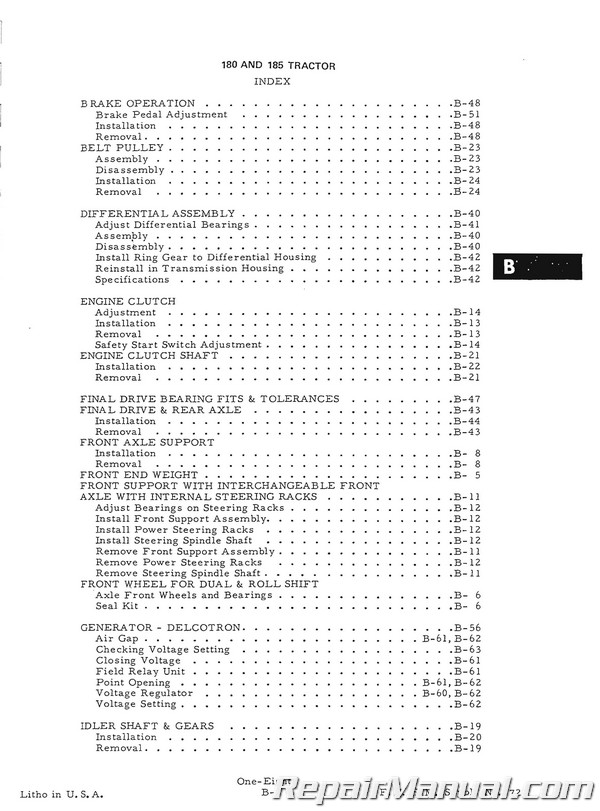

TRACTOR

BRAKE OPERATION

Brake Pedal Adjustment

Installation

Removal

BELT PULLEY

Assembly

Disassembly

Installation

Removal

DIFFERENTIAL ASSEMBLY

Adjust Differential Bearings

Assembly

Disassembly

Install Ring Gear to Differential Housing

Reinstall in Transmission Housing

Specifications

ENGINE CLUTCH

Adjustment

Installation

Removal

Safety Start Switch Adjustment

ENGINE CLUTCH SHAFT

Installation

Removal

FINAL DRIVE BEARING FITS & TOLERANCES

FINAL DRIVE & REAR AXLE

Installation

Removal

FRONT AXLE SUPPORT

Installation

Removal

FRONT END WEIGHT

FRONT SUPPORT WITH INTERCHANGEABLE FRONT AXLE WITH INTERNAL STEERING RACKS

Adjust Bearings on Steering Racks

Install Front Support Assembly

Install Power Steering Racks

Install Steering Spindle Shaft

Remove Front Support Assembly

Remove Power Steering Racks

Remove Steering Spindle Shaft

FRONT WHEEL FOR DUAL & ROLL SHIFT

Axle Front Wheels and Bearings

Seal Kit

GENERATOR – DELCOTRON

Air Gap

Checking Voltage Setting

Closing Voltage

Field Relay Unit

Point Opening

Voltage Regulator

Voltage Setting

IDLER SHAFT & GEARS

Installation

Removal

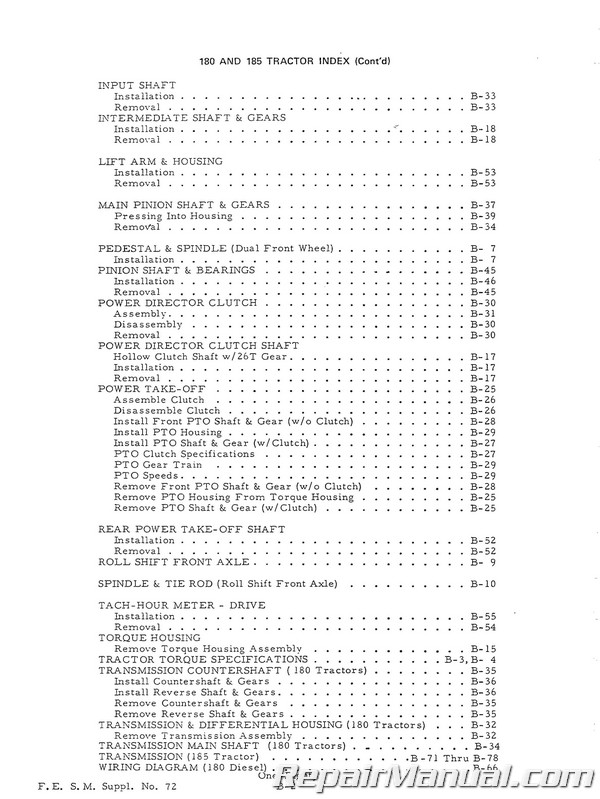

INPUT SHAFT

Installation

Removal

INTERMEDIATE SHAFT & GEARS

Installation

Removal

LIFT ARM HOUSING

Installation

Removal

MAIN PINION SHAFT & GEARS

Pressing Into Housing

Removal

PEDESTAL & SPINDLE (Dual Front Wheel)

Installation

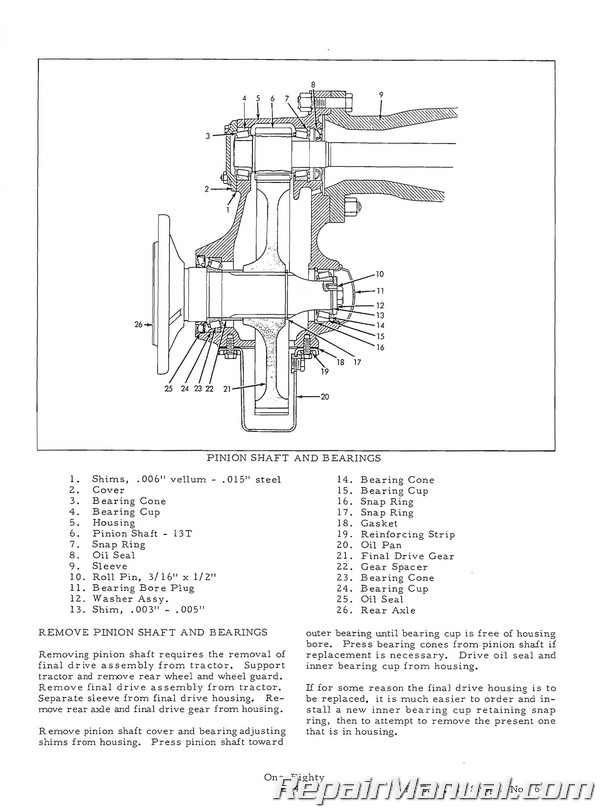

PINION SHAFT & BEARINGS

Installation

Removal

POWER DIRECTOR CLUTCH

Assembly

Disassembly

Removal

POWER DIRECTOR CLUTCH SHAFT

Hollow Clutch Shaft w/26T Gear

Installation

Removal

POWER TAKE-OFF

Assemble Clutch

Disassemble Clutch

Install Front PTO Shaft & Gear (w/o Clutch)

Install PTO Housing

Install PTO Shaft & Gear (w/Clutch)

PTO Clutch Specifications

PTO Gear Train

PTO Speeds

Remove Front PTO Shaft & Gear (w/o Clutch)

Remove PTO Housing From Torque Housing

Remove PTO Shaft & Gear (w/Clutch)

REAR POWER TAKE-OFF SHAFT

Installation

Removal

ROLL SHIFT FRONT AXLE

SPINDLE k TIE ROD (Roll Shift Front Axle)

TACH-HOUR METER – DRIVE

Installation

Removal

TORQUE HOUSING

Remove Torque Housing Assembly

TRACTOR TORQUE SPECIFICATIONS

TRANSMISSION COUNTERSHAFT ( 180 Tractors)

Install Countershaft k Gears

Install Reverse Shaft k Gears

Remove Countershaft k Gears

Remove Reverse Shaft k Gears

TRANSMISSION k DIFFERENTIAL HOUSING (180 Tractors)

Remove Transmission Assembly

TRANSMISSION MAIN SHAFT (180 Tractors)

TRANSMISSION (185 Tractor)

WIRING DIAGRAM (180 Diesel)

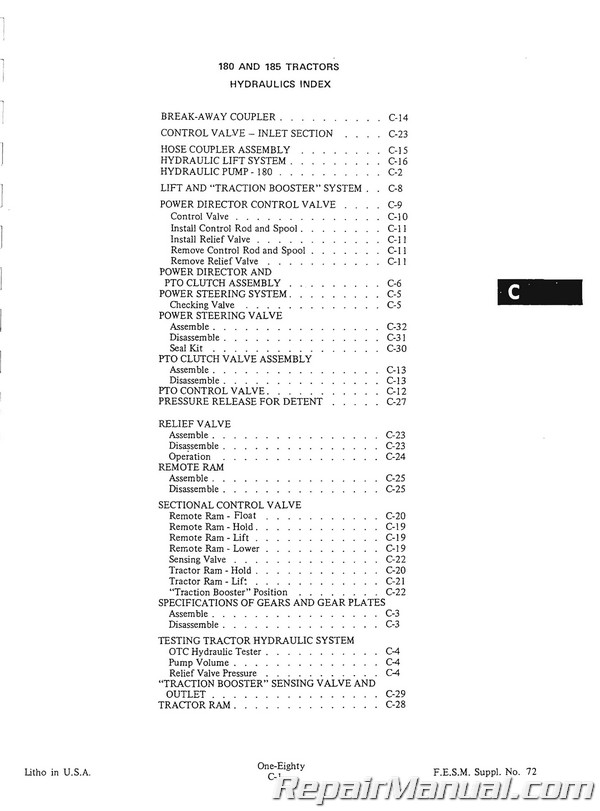

HYDRAULICS

BREAK-AWAY COUPLER

CONTROL VALVE – INLET SECTION

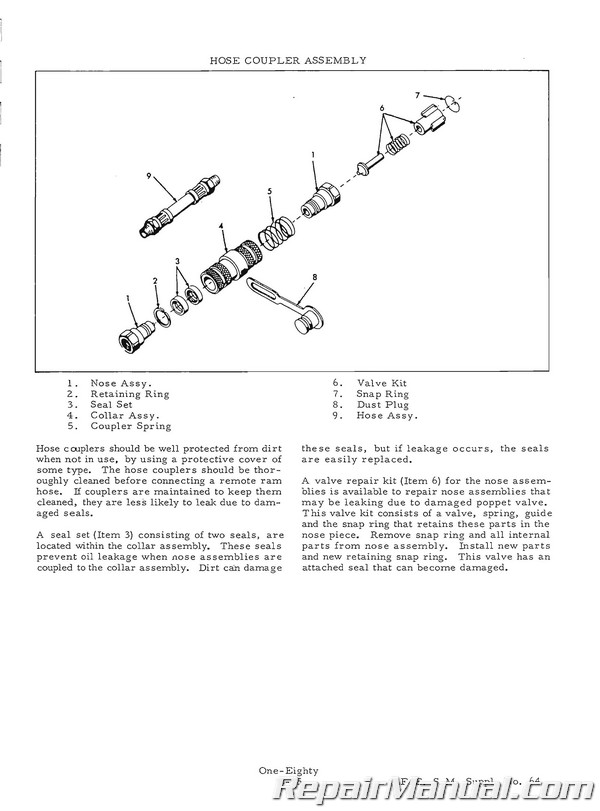

HOSE COUPLER ASSEMBLY

HYDRAULIC LIFT SYSTEM

HYDRAULIC PUMP-180

LIFT AND “TRACTION BOOSTER” SYSTEM

POWER DIRECTOR CONTROL VALVE

Control Valve

Install Control Rod and Spool

Install Relief Valve

Remove Control Rod and Spool

Remove Relief Valve

POWER DIRECTOR AND

PTO CLUTCH ASSEMBLY

POWER STEERING SYSTEM

Checking Valve

POWER STEERING VALVE

Assemble

Disassemble

Seal Kit

PTO CLUTCH VALVE ASSEMBLY

Assemble

Disassemble

PTO CONTROL VALVE

PRESSURE RELEASE FOR DETENT

RELIEF VALVE

Assemble

Disassemble

Operation

REMOTE RAM

Assemble

Disassemble

SECTIONAL CONTROL VALVE

Remote Ram – Float

Remote Ram – Hold

Remote Ram – Lift

Remote Ram – Lower

Sensing Valve

Tractor Ram – Hold

Tractor Ram – Lift

“Traction Booster” Position

SPECIFICATIONS OF GEARS AND GEAR PLATES

Assemble

Disassemble

TESTING TRACTOR HYDRAULIC SYSTEM

OTC Hydraulic Tester

Pump Volume

Relief Valve Pressure

TRACTION BOOSTER” SENSING VALVE AND OUTLET

TRACTOR RAM

OPTIONAL EQUIPMENT & ACCESSORIES