Description

This Official 2014 Polaris Ranger 400 Factory Service Manual Provides detailed service information, step-by-step repair instruction and maintenance specifications for 2014 Polaris Ranger 400 ATVs.

2014 Polaris Ranger 400 Service Manual Table of Contents

Chapter 1: General Information

Chapter 2: Maintenance

Chapter 3: Engine

Chapter 4: Fuel System – Carbureted

Chapter 5: Body / Steering / Suspension

Chapter 6: Clutching

Chapter 7: Final Drive

Chapter 8: Transmission

Chapter 9: Brakes

Chapter 10: Electrical

2014 Polaris Ranger 400 Service Manual Index of Topics

Chapter 1 General Information

Vehicle Identification

Model Number Designation

Vehicle Identification Number (vin) Designation

Engine Designation Number

Vin And Engine Serial Number Locations

Vin And Engine Serial Number Locations

Vehicle Information

Publication Numbers

Replacement Keys

Special Tools

General Specifications

Model: Ranger 400 Midsize

Model: Ranger 400 Midsize

Misc Specifications And Charts

Conversion Table

Standard Bolt Torque Specification

Metric Bolt Torque Specification

Sae Tap / Drill Sizes

Metric Tap / Drill Sizes

Decimal Equivalents

Chapter 2 Maintenance

Periodic Maintenance Chart

Periodic Maintenance Overview

Break-in Period

Maintenance Chart Key

Pre-ride – 25 Hour Maintenance Interval

50- 100 Hour Maintenance Interval

100 – 300 Hour Maintenance Interval

Grease Lubrication Points

Service Products And Lubricants

Polaris Lubricants, Maintenance And Service Products

Fluid Maintenance References

Component Quick Reference

Component Quick Reference, Continued

General Vehicle Inspection And Maintenance

Pre-ride / Daily Inspection

Frame, Nuts, Bolts, And Fasteners

Shift Cable Inspection

Shift Cable Adjustment

Fuel System And Air Intake

Fuel System

Fuel Lines

Fuel Pump/filter

Vent Lines

Throttle Pedal Inspection

Throttle Freeplayadjustment

Air Filter Service

Engine Air Intake Inspection

Pvt Air Intake Inspection

Air Intake Exploded View

Engine

Compression And Leakdown Test

Breather Filter Inspection

Breather Hose

Flywheel Housing Drain Plug (if Equipped)

Engine Oil Level

Engine Oil And Filter Change

Oil Pump Priming Procedure

Valve Clearance

Intake Valve Clearance Adjustment

Exhaust Valve Clearance Adjustment

Exhaust Pipe Clean Out

Transmission And Gearcases

Transmission Lubrication

Front Gearcase Lubrication

Cooling System

Liquid Cooling System Overview

Coolant Level Inspection

Coolant Strength / Type

Cooling System Hoses

Radiator Inspection / Cleaning

Coolant Drain / Radiator Removal

Final Drive / Wheel And Tire

Wheel And Hub Torque Table

Cv Shaft Boot Inspection

Wheel Removal

Wheel Installation

Tire Inspection

Tire Pressure

Electrical And Ignition System

Battery Maintenance

Battery Fluid Level (conventional Battery)

Battery Removal

Battery Installation

Battery Storage

Battery Charging

Spark Plug Service

Engine To Frame Ground

Steering

Steering

Tie Rod End / Steering Inspection

Wheel Toe Alignment Inspection

Toe Adjustment

Suspension

Suspension Inspection

Spring Pre-load Adjustment

Stabilizer Bar Pivot Lubrication

Suspension Pivot Point Lubrication

Brake System

Brake Fluid Inspection

Brake Hose And Fitting Inspection

Brake Pad / Disc Inspection

Chapter 3 Engine

Specifications

Torque Specifications

Engine Fastener Torque Patterns

Ranger 400 Midsize Engine Service Data (eh46ple 455cc Carbureted)

Ranger 400 Midsize Engine Service Data (eh46ple 455cc Carbureted)

Special Tools

Special Tools

General Engine Service

Accessible Components

Engine Removal

Engine Installation Notes

Crankshaft Straightening

Engine Lubrication –

Oil Pressure Test-

Oil Flow-

Oil Flow Diagram

Engine Exploded View

Cooling System

Cooling System Layout And Testing

Engine Disassembly

Engine Removal

Cam Chain Tensioner / Rocker Arm /camshaft Removal

Cam Chain Tensioner Inspection

Rocker Arm/shaft Inspection

Camshaft Removal

Automatic Compression Release Removal / Inspection

Automatic Compression Release Installation

Camshaft Inspection

Cylinder Head Removal

Cylinder Head Exploded View

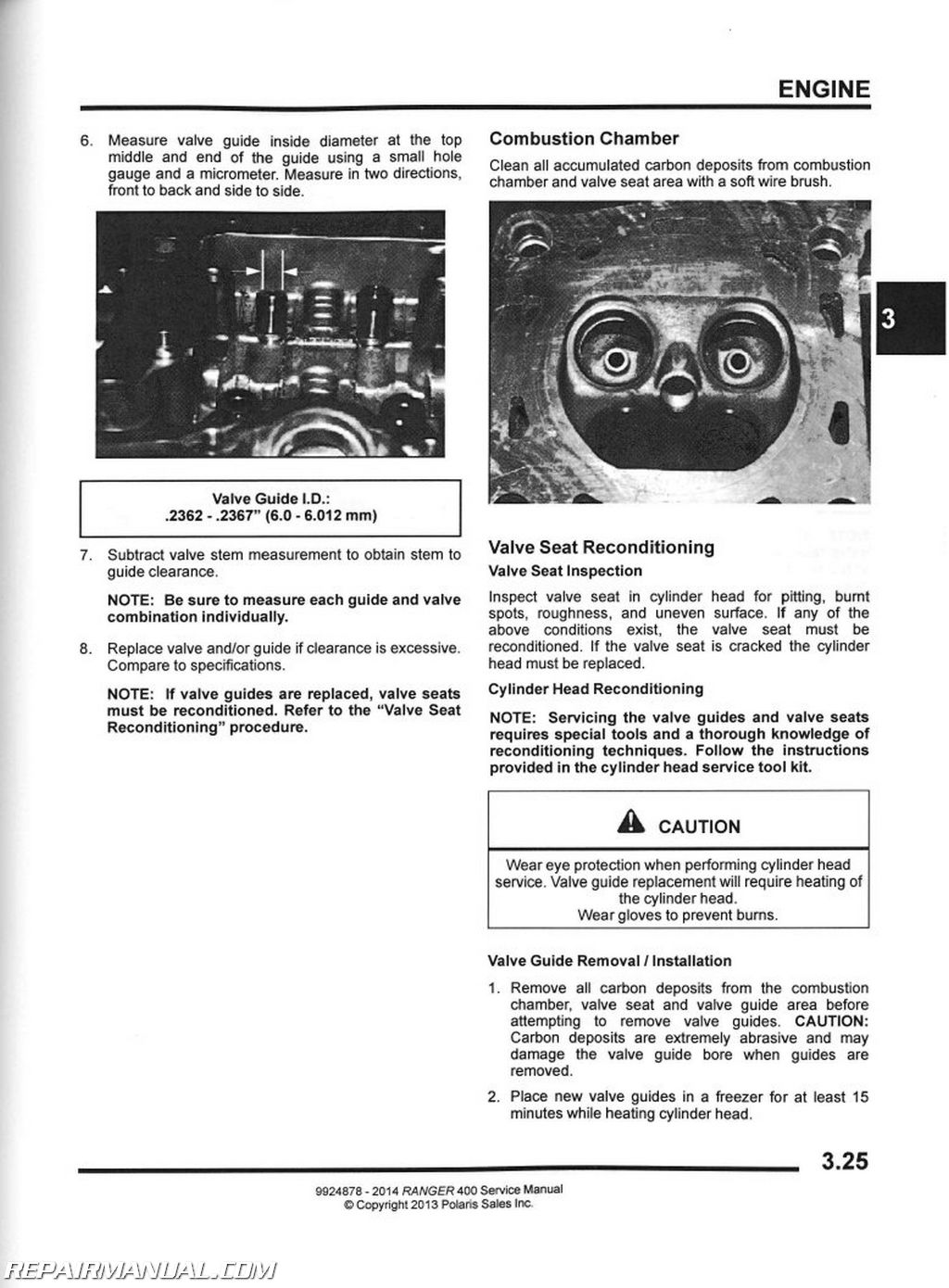

Cylinder Head Inspection

Cylinder Head Warpage

Cylinder Head Disassembly

Valve Inspection

Combustion Chamber

Valve Seat Reconditioning

Cylinder Head Assembly

Valve Sealing Test

Valve Clearance Adjustment

Cylinder / Piston Removal And Inspection

Piston Removal

Cylinder Inspection

Cylinder Hone Selection / Honing Procedure

Honing To Oversize

Cleaning The Cylinder After Honing

Piston-to-cylinder Clearance

Piston / Rod Inspection

Piston Identification

Piston Ring Installed Gap

Crankcase Disassembly

Starter Drive Removal / Inspection

Flywheel And Stator Removal / Inspection

Cam Chain/tensioner Blade

One Way Valve

Crankcase Separation

Oil Pump Removal / Inspection

Oil Pump Assembly

Counter Balancer Shaft Removal / Inspection

Crankshaft Removal / Inspection

Crankcase Bearing Inspection

Oil Seal / Mechanical Seal Removal(engine Disassembled)

Crankcase Inspection

Bearing Installation

End Play Inspection / Adjustment

Crankshaft End Play Adjustment

Counter Balancer Shaft End Play Adjustment

Oil Pump Shaft End Play Adjustment

Engine Reassembly

Pump Shaft Oil Seal Installation

Crankshaft/ Counter Balance / Oil Pump Installation

Crankcase Assembly

Water Pump Mechanical Seal Installation

Water Pump Mechanical Seal Removal(engine Installed)

One Way Valve Installation

Cam Chain Drive Sprocket Installation

Tensioner Blade Installation

Piston Ring Installation

Piston Installation

Cylinder Installation

Cylinder Head Installation

Cam Chain / Camshaft Installation

Camshaft Timing

Camshaft Timing Illustration

Cam Chain Tensioner Installation

Stator, Flywheel And Starter Drive Installation

Rocker Shaft / Rocker Arm Assembly Installation

Thermostat Installation

Oil Pipes

Oil Pump Priming Procedure

Troubleshooting

Engine

Spark Plug Fouling

Cooling Troubleshooting

Chapter 4 Fuel System – Carbureted

Special Tools

Carburetor Jetting

Jetting Guidelines

Mikuni Jet Part Numbers

Mikuni Cv Carburetor

Exploded View

System Function – Mikuni Cv Carb

Vent Systems – Mikuni Cv Carb

Operation – Mikuni Cv Carb

Pilot System (idle And Slow Speed)

Starter System (choke Or Enrichment)

Float System

Main System

Pilot Screw

Air/fuel Mixture Ratio

Jet Needle

Needle Jet

Throttle Opening Vs Fuel Flow

Carburetor Service

Carburetor Removal

Carburetor Disassembly

Carburetor Cleaning

Carburetor Inspection

Float Height Adjustment

Needle And Seat Leak Test

Fuel Level

Carburetor Assembly

Air Box Assembly

Fuel Tank Assembly

Fuel Tank/fuel Pump Exploded View

Fuel Tank Removal

Fuel Tank Installation

Fuel Pump

Replacement

Fuel Filter Replacement

Troubleshooting

Fuel Starvation / Lean Mixture

Rich Mixture

Idle Too High

Idle Too Low

Erratic Idle

Chapter 5 Body I Steering I Suspension

Torque Specifications

Special Tools

Multi-function Pliers

Chassis/main Frame

Exploded View

Body Exploded Views

Dash Instruments / Controls

Hood / Dash / Front Fascia

Floor/rear Fenders

Seat Mounting /seat Belts

Rear Cargo Box

Cargo Box – Tailgate / Box Support

Box Removal

Box Installation

Body Component Removal

Lower Seat Base

Front Bumper

Wheel Well Panels

Fenders/foot Pads

Hood/dash

Floors

Steering Assembly

Exploded View

Front A-arm

Replacement

Front Strut

Exploded View

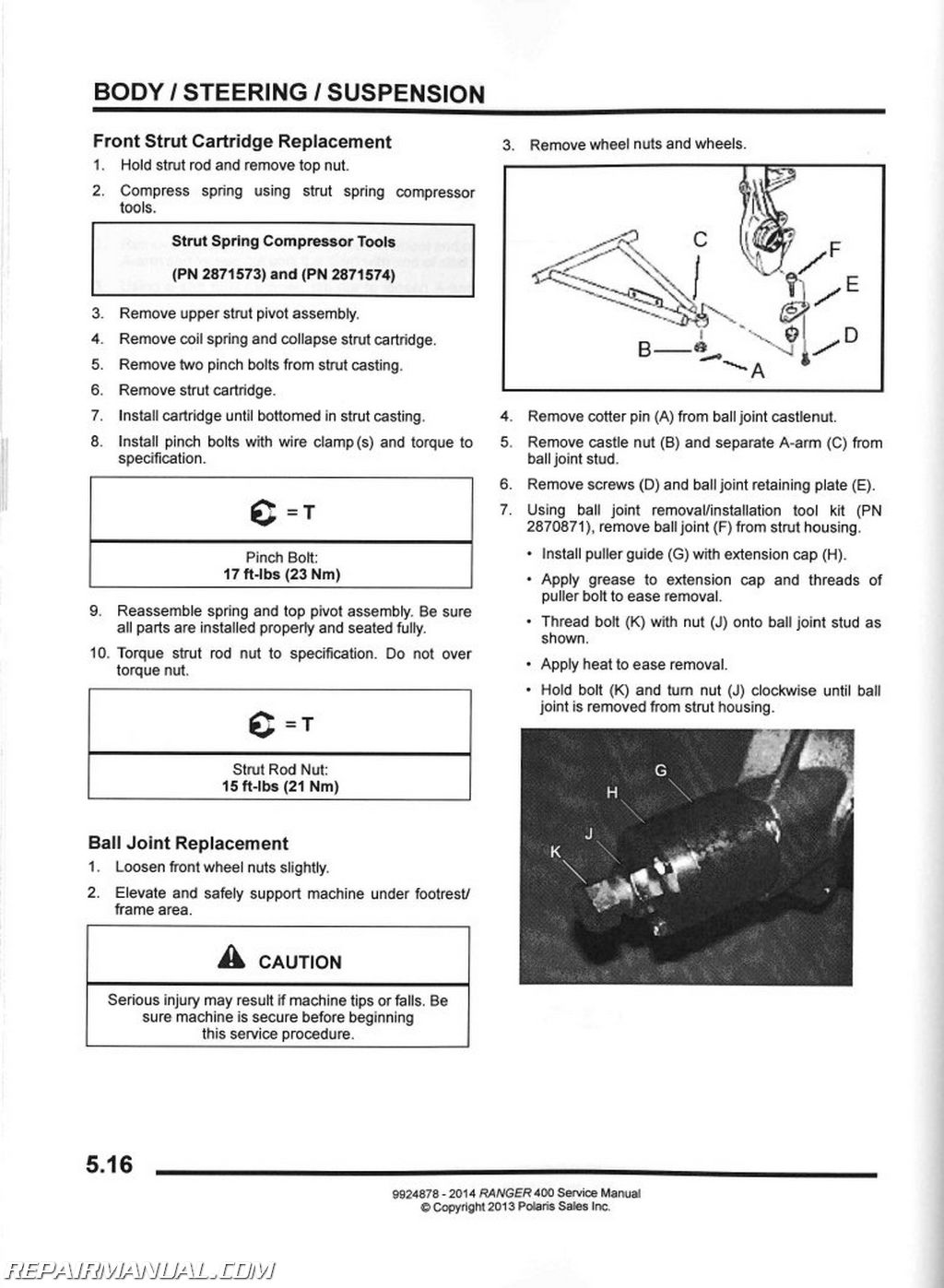

Front Strut Cartridge Replacement

Ball Joint Replacement

Rear A-arms

Removal/replacement

Installation

Exploded View

Rear Stabilizer Bar / Linkage

Removal / Installation

Exploded View

Shocks/springs

Exploded View

Shock Removal/installation

Shock Replacement

Decal Replacement

Chapter 6 Clutching

Special Tools And Supplies

Torque Specifications

Pvt System Fastener Torques

Pvt System Overview

Clutching Chart

General Operation

Drive Clutch Operation

Driven Clutch Operation

Pvt Break-in (drive Belt / Clutches)

Maintenance/inspection

Overheating /diagnosis

Pvt System Service

Pvt Sealing, Guard, And Ducting Components

Disassembly

Assembly

Drive Belt

Belt Deflection (tension)

Belt Removal

Belt Inspection

Belt Installation

Pvt Break-in (drive Belt/clutches)

Clutch Alignment / Offset / Center Distance

Clutch Alignment

Clutch Offset

Setting Center-to-center Distance

Drive Clutch Service

Exploded View

Clutch Inspection

Shift Weight Inspection

Clutch Disassembly

Spider Removal

Roller, Pin, And Thrust Washer Inspection

Bushing Service

Moveable Sheave – Bushing Removal

Moveable Sheave – Bushing Installation

Clutch Cover – Bushing Removal

Clutch Cover – Bushing Installation

Clutch Assembly

Driven Clutch Service

Exploded View

Clutch Disassembly / Inspection

Bushing Service

Moveable Sheave – Bushing Installation

Clutch Assembly

Troubleshooting

Chapter 7 Final Drive

Special Tools

Torque Specifications

Wheel And Hub Torque Table

Front Hub/bearing

Hub Removal/inspection

Hubstrut Bearing Replacement

Hub Installation

Front Hub/wheel Exploded View

Front Drive Shaft

Removal

Installation

Front Gearcase – Centralized Hilliard

Exploded View

All Wheel Drive Operation

Awd Diagnosis

Gearcase Removal

Gearcase Installation

Disassembly / Inspection

Assembly/inspection

Setting Ring Gear Backlash

Rear Bearing Carrier

Inspection

Removal

Disassembly

Assembly

Installation

Rear Drive Shaft

Removal

Installation

Drive Shaft Service

Drive Shaft/cv Joint Handling Tips

Outer Cv Joint / Boot Replacement

Inner Plunging Joint / Boot Replacement

Drive Shaft Exploded View

Propshaft U-joint Service

Removal / Installation

Front Propshaft Components

Disassembly

Assembly

Chapter 8 Transmission

Specifications

Torque Specifications

Lubrication

Shift Lever

Removal

Installation

Shift Cable

Inspection

Adjustment

Transmission Service

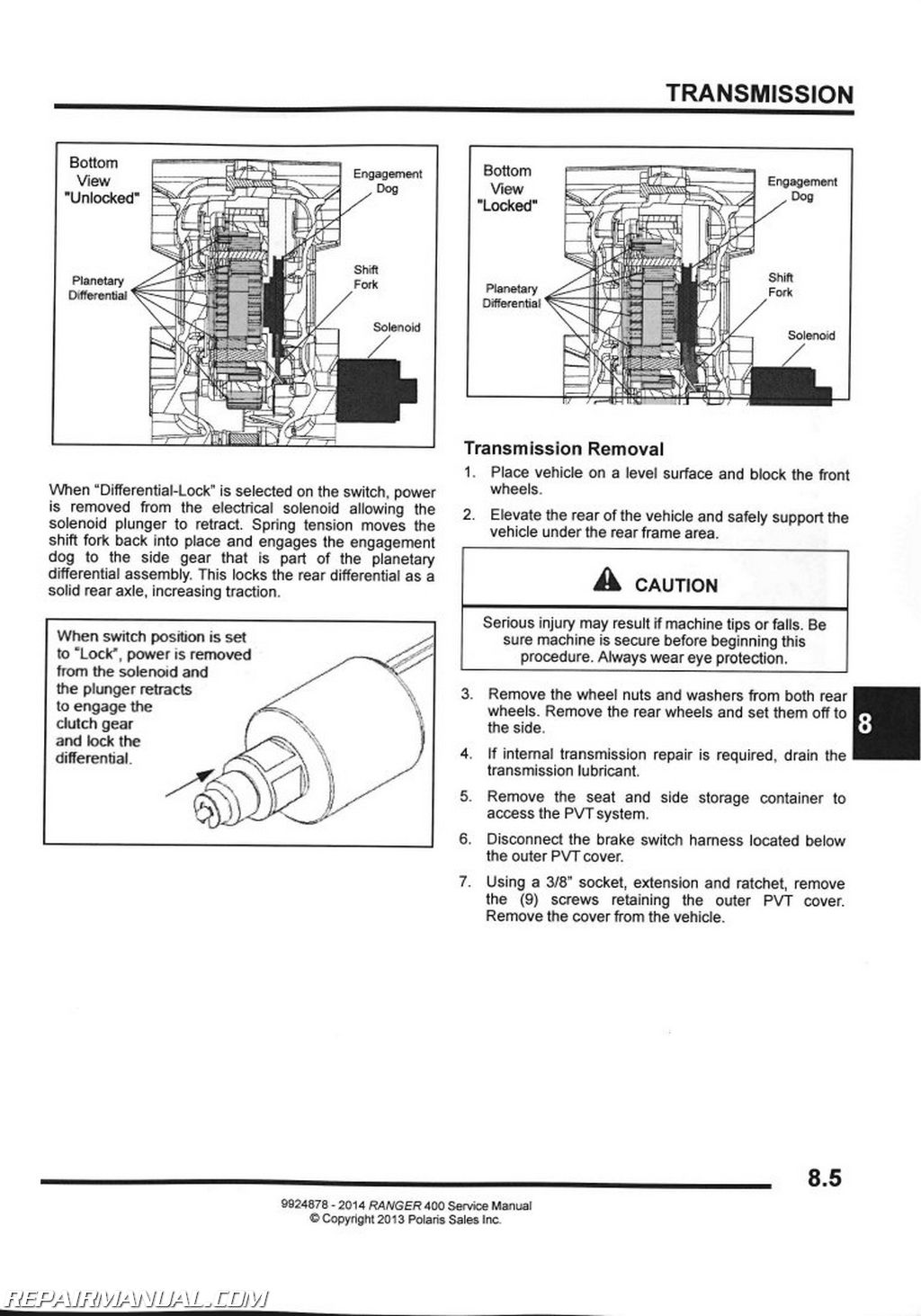

General Operation

Transmission Removal

Transmission Disassembly

Snorkel / Output Gear Backlash Procedure

Transmission Assembly

Transmission Installation

Troubleshooting

Troubleshooting Checklist

Transmission Exploded View

Ranger 400

Chapter 9 Brakes

General Specifications

Torque Specifications

Special Tools

Brake System Service Notes

Brake Noise Troubleshooting

Hydraulic Brake System Operation

Brake System Exploded View

Master Cylinder

Removal

Installation

Brake Pressure Switch

Foot Brake Pedal

Pedal Removal

Pedal Installation

Brake Bleeding / Fluid Change

Front Brake Pads

Pad Removal / Disassembly

Pad Inspection

Pad Assembly / Installation

Pad Adjustment

Front Caliper

Front Caliper Exploded View

Caliper Removal

Front Caliper Disassembly

Caliper Inspection

Caliper Assembly

Caliper Installation

Front Brake Disc

Disc Inspection

Disc Removal / Replacement

Rear Brake Pad Service

Pad Removal

Pad Inspection

Rear Pad Installation

Rear Brake Caliper Service

Caliper Exploded View

Caliper Removal

Rear Caliper Disassembly

Rear Caliper Inspection

Rear Caliper Assembly

Rear Caliper Installation

Rear Brake Disc

Disc Runout

Disc Inspection

Disc Removal / Replacement

Troubleshooting

Brakes Squeal / Poor Brake Performance

Pedal Vibration

Caliper Overheats (brakes Drag)

Brakes Lock

Chapter 10 Electrical

General Information

Special Tools

Electrical Service Notes

Battery Conductance Analyzer

Components Under Hood

Switches / Controls

Headlight Switch

Awd / 2wd / Turf Switch

Differential Solenoid

Brake Pressure Switch

Gear Indicator Light Circuit Operation

Indicator Lamp Replacement

Hour Gauge

All Wheel Drive (awd) Coil

Operation Overview

Diagnosing System Failures

Headlights

Headlight Adjustment

Headlight Bulb Replacement

Headlight Housing Removal

Headlight Housing Installation

Tail Light / Brake Light

Led Lamp Replacement

Cooling System

Coolant Temperature Sensor

Cooling System Diagram / Overview

Fan Control Circuit Operation

Fan Control Circuit Bypass Test

Relays / Solenoid Driver

Operation

Fuses / Circuit Breaker

Operation

Acs-hub Module / Fan Relay

Operation

Charging System

Current Draw – Key Off

Charging System “break Even” Test

Charging System Alternator Tests

Regulator / Rectifier Test

Charging System Testing Flowchart

Battery Service

Battery Terminals/bolts

Battery Terminal Block

Battery Activation

Battery Inspection

Battery Removal / Installation

Conventional Battery Testing

Ocv- Open Circuit Voltage Test

Specific Gravity Test

Load Test

Charging Procedure

Off Season Storage

Starter System

Troubleshooting

Voltage Drop Test

Starter Motor Disassembly

Brush Inspection / Replacement

Armature Testing

Starter Reassembly

Starter Drive

Starter Solenoid Bench Test

Starter Solenoid Operation

Starting System Testing Flow Chart