Description

This Official 2014 Polaris Ranger 570 UTV Factory Service Manual provides detailed service information, step-by-step repair instruction and maintenance specifications for 2014 Polaris Ranger 570 Side by Sides.

Table of Contents

Chapter 1: General Information

Chapter 2: Maintenance

Chapter 3: Engine

Chapter 4: Electronic Fuel Injection

Chapter 5: Body / Steering / Suspension

Chapter 6: Clutching

Chapter 7: Final Drive

Chapter 8: Transmission

Chapter 9: Brakes

Chapter 10: Electrical

Service Manual Index of Topics

Chapter 1: General Information

Chapter 2: Maintenance

Chapter 3: Engine

Chapter 4: Electronic Fuel Injection

Chapter 5: Body / Steering / Suspension

Chapter 6: Clutching

Chapter 7: Final Drive

Chapter 8: Transmission

Chapter 9: Brakes

Chapter 10: Electrical

Chapter 1 General Information

Vehicle Information

Model Number Designation

Vehicle Identification Number (vin) Designation

Engine Designation Number

Vin / Engine Number Location

Publication Numbers

Replacement Keys

Special Tools

General Specifications

Model: 2014 Ranger 570 / 570 Eps / Int’l

2014 Ranger 570 / 570 Eps / Int’l

Model: 2014 Ranger 570 Crew / 570 Crew Eps

2014 Ranger 570 Crew

Misc Specifications And Charts

Conversion Table

Standard Bolt Torque Specification

Metric Bolt Torque Specification

Sae Tap/drill Sizes

Metric Tap / Drill Sizes

Decimal Equivalents

Chapter 2 Maintenance

Special Tools

Periodic Maintenance Chart

Periodic Maintenance Overview

Break-in Period

Maintenance Chart Key

Pre-ride – 25 Hour Maintenance Interval

50- 100 Hour Maintenance Interval

100 – 300 Hour Maintenance Interval

Grease Lubrication Points

Service Products And Lubricants

Polaris Lubricants, Maintenance And Service Products

Fluid Maintenance References

Component Quick Reference

Component Quick Reference, Continued

General Maintenance

Pre-ride / Daily Inspection

Frame, Nuts, Bolts, And Fasteners

Shift Cable Inspection

Shift Cable Adjustment

Fuel System And Air Intake

Fuel System

Fuel Lines

Fuel Pump/filter

Vent Lines

Throttle Pedal Inspection

Throttle Freeplay Adjustment

Air Filter Service

Engine Air Intake Inspection

Pvt Air Intake Inspection

Engine

Compression And Leakdown Test

Breather Valve Inspection

Breather Hose

Engine Oil Level

Engine Oil And Filter Change

Valve Clearance

Transmission And Gearcases

Transmission Lubrication

Front Gearcase Lubrication

Cooling System

Liquid Cooling System Overview

Coolant Level Inspection

Coolant Strength / Type

Cooling System Hoses

Radiator Inspection / Cleaning

Coolant Drain / Radiator Removal

Final Drive / Wheel And Tire

Wheel And Hub Torque Table

Cv Shaft Boot Inspection

Wheel Removal

Wheel Installation

Tire Inspection

Tire Pressure

Electrical And Ignition System

Battery Maintenance

Battery Fluid Level (conventional Battery)

Battery Removal

Battery Installation

Battery Storage

Battery Charging

Spark Plug Service

Main Frame/engine Ground

Steering

Steering Inspection Note

Tie Rod End / Steering Inspection

Wheeltoe Alignment Inspection

Toe Adjustment

Suspension

Suspension Inspection

Spring Pre-load Adjustment

Stabilizer Bar Pivot Lubrication

Suspension Pivot Point Lubrication

Brake System

Brake Fluid Inspection

Brake Hose And Fitting Inspection

Brake Pad / Disc Inspection

Chapter 3 Engine

General Information

Special Tools

Engine Lubrication Specifications

Oil Pressure Test

Engine Oil Flow Chart

Engine Specifications

Engine Detail – Torque Values / Sequences / Assembly Notes

Main Engine Components – Torque Specification And Sequence

Crankcase / Timing Chain Guides / Oil Pickup / Regulator Valve

Cylinder / Oil Filter / Oil Pump / Breather

Camshafts / Cylinder Head / Flywheel / Idler Gears / Stator Cover

Spark Plug / Starter / Throttle Body / Valve Cover

Piston / Crankshaft / Balance Shaft

Engine Cooling System

Cooling System Assembly View And Coolant Flow Diagram

Cooling System Specifications

Cooling System Pressure Test

Pressure Cap Test

Radiator

Coolant Drain / Radiator Removal

Thermostat Replacement

Cooling System Bleeding Procedure

Water Pump Cover And Impeller Service (stator Cover Remains On Engine)

Water Pump Mechanical Seal / Oil Seal Replacement

Engine Service

Accessible Engine Components

Top-end Service (engine In Chassis)

Engine Removal

Engine Installation

Engine Break-in Period

Engine Mounting And Torque Values

Engine Lubrication Specifications

Setting Tdc (top-dead-center)

Engine Disassembly / Inspection – Top End

Valve Cover Removal

Camshaft Removal

Camshaft Sprocket Inspection

Camshaft / Camshaft Bore Inspection

Exhaust Camshaft Decompression Mechanism

Cam Chain And Guide Service

Cylinder Head Removal

Cylinder Head Disassembly

Cylinder Head Inspection

Cylinder Head Warp Inspection

Valve Inspection

Combustion Chamber Cleaning

Valve Seat Reconditioning

Cylinder Removal

Cylinder Inspection

Piston Removal

Piston-to-cylinder Clearance

Piston / Rod Inspection

Piston Ring Installed Gap

Honing To Oversize

Cylinder Hone Selection / Honing Procedure

Cleaning The Cylinder After Honing

Camshaft Installation / Timing

Camshaft Timing – Quick Reference

Valve Cover Installation

Engine Assembly- Top End

Piston Ring Installation

Piston / Connecting Rod Assembly

Cylinder Installation

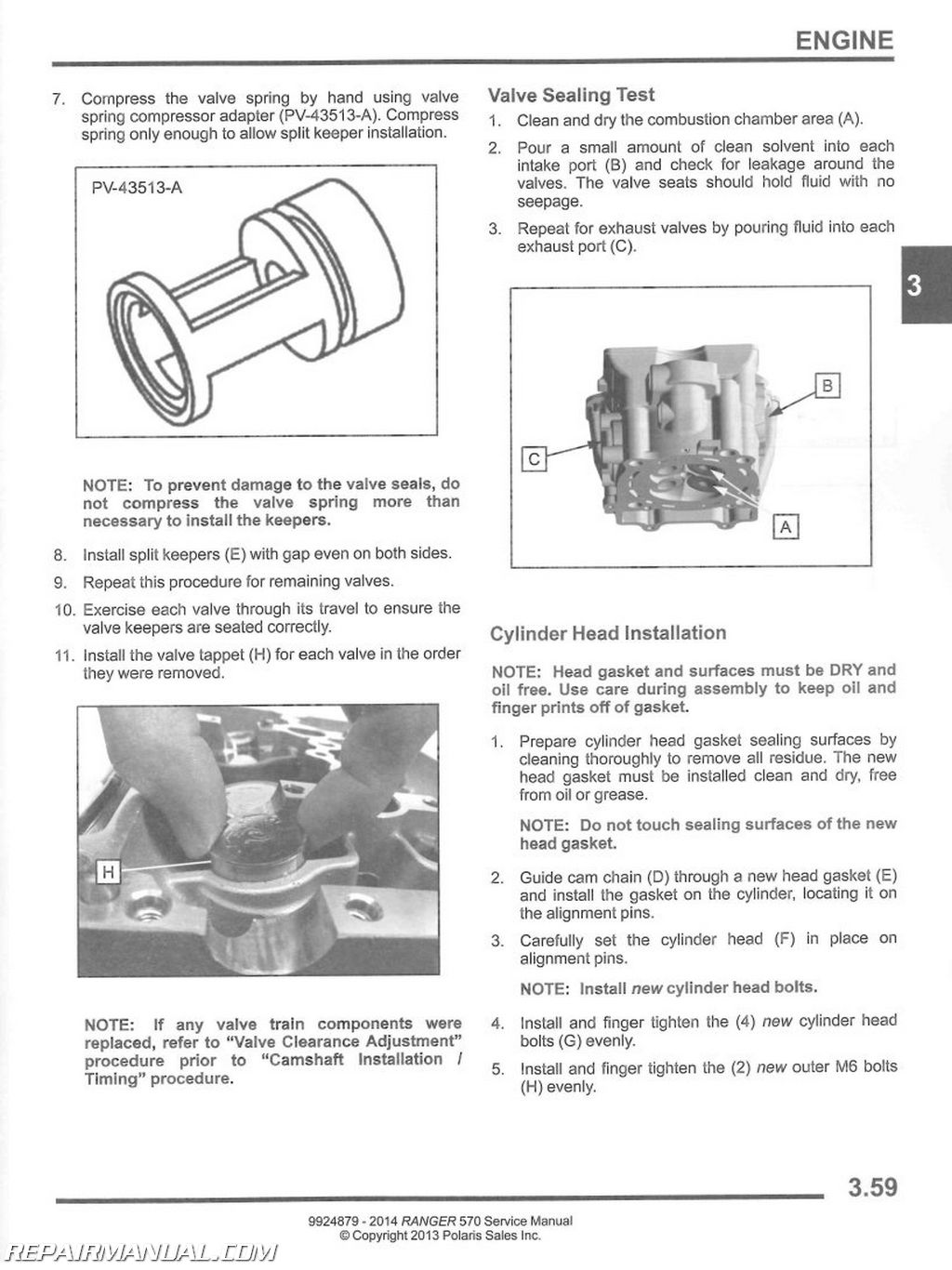

Cylinder Head Assembly

Valve Sealing Test

Cylinder Head Installation

Valve Clearance Check / Adjustment

Intake Valve Lash – Tappet Selection Matrix

Exhaust Valve Lash – Tappet Selection Matrix

Engine Disassembly / Inspection – Lower End

Crankcase Disassembly

Flywheel/stator Housing Removal

Starter One-way Clutch Inspection

Stator Removal

Oil Pump Removal

Oil Pump Assembly

Crankcase Breather Service

Crankcase Separation

Balance Shaft Removal / Inspection

Crankshaft Removal

Crankshaft Inspection

Pto Side Crankcase Bearing Service

Mag Side Crankcase Bearing Service

Oil Pickup Assembly Inspection

Oil Pressure Regulator (bypass) Valve Inspection

Crankcase Inspection

Engine Assembly-lower End

Crankcase Assembly-pto Side

Balance Shaft Installation / Timing

Final Crankcase Assembly

Starter One-way Clutch Installation

Flywheel Installation

Stator / Stator Cover Installation

Troubleshooting

Engine

Cooling System

Chapter 4 Electronic Fuel Injection

General Information

Special Tools

Service Notes

Efi Operation Overview

Efi System Assembly View

Efi System Component Locations

Principal Components

Initial Priming / Starting Procedure

Electronic Control Unit (ecu)

Operation Overview

Ecu Service

Ecu Replacement

Fuel Tank

Operation Overview

Assembly View

Fuel Lines-quick Connect

Fuel Tank Removal

Fuel Tank Installation

Fuel Sender Test

Fuel Pump Test

Fuel Pump Replacement

Temp / Manifold Absolute Pressure Sensor (t-map)

Operation Overview

T-map Sensor Test

T-map Sensor Replacement

Crankshaft Position Sensor (cps)

Operation Overview

Cps Test

Cps Replacement

Fuel Injector

Operation Overview

Fuel Injector Troubleshooting

Fuel Injector Test

Fuel Injector Replacement

Idle Air Control (iac)

Operation Overview

Iac Test

Iac Replacement

Throttle Position Sensor (tps)

Operation Overview

Tps Resistance Tests

Tps Tester / Regulator

Tps Replacement

Engine Coolant Temperature Sensor (ect)

Operation Overview

Ect Sensor Test

Ect Sensor Replacement

Efi Diagnostics

Instrument Cluster Trouble Code Display

Diagnostic Trouble Code Chart

Efi Troubleshooting

Digital Wrench® Operation

Digital Wrench® Diagnostic Software Overview

Special Tools (also Refer To The Beginning Of This Chapter)

Diagnostic Software Version

Ecu Replacement

Guided Diagnostic Available

Digital Wrench® Communication Errors

Digital Wrench® – Diagnostic Connector

Digital Wrench® Serial Number Location

Digital Wrench® Version And Update Id

Digital Wrench® Updates

Digital Wrench® Feature Map

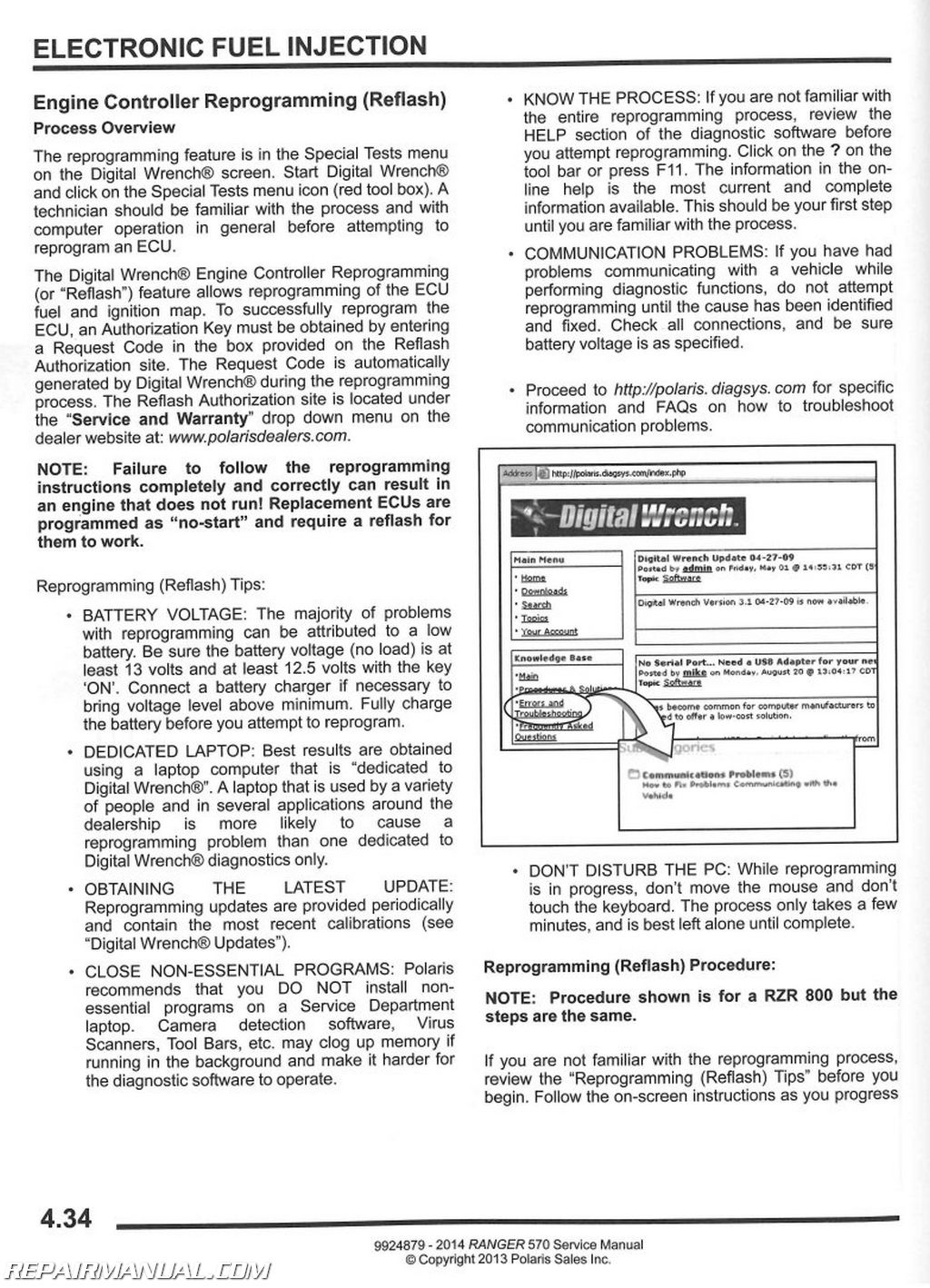

Engine Controller Reprogramming (reflash)

Efi System Electrical Diagram

Chapter 5 Body / Steering / Suspension

Torque Specifications

Special Tools

Chassis /body

570 Efi Frame Assembly View

570 Efi Crew Frame Assembly View

570 Cab Frame

570 Crew Cab Frame

Dash Instruments / Controls:

Hood / Dash / Front Fascia

570 Efi Floor / Rear Fenders

570 Efi Seat Mounting / Seat Belts

570 Efi Crew Floor / Rear Fenders

570 Efi Crew Seat Mounting / Seat Belts

Rear Cargo Box

Cargo Box – Tailgate / Box Support

Box Removal

Box Installation

Body Component Removal

Lower Seat Base

Front Bumper

Wheel Well Panels

Fenders/foot Pads

Hood/dash

Floors

Decal Replacement

Steering Assembly

Assembly View (non-eps)

Assembly View (eps)

Steering Wheel Removal (non-eps Models)

Steering Shaft Removal (non-eps Models)

Steering Shaft Bearing Replacement

Steering Wheel Removal (eps Models)

Power Steering Unit Removal

Power Steering Unit Installation

Front Strut

Assembly View

Front Strut Cartridge Replacement

Ball Joint Replacement

Rear A-arms

Removal/replacement

Installation

Assembly View

Rear Stabilizer Bar / Linkage

Removal / Installation

Assembly View

Shocks /springs

Assembly View

Shock Removal / Installation

Shock Replacement

Chapter 6 Clutching

Special Tools And Supplies

Torque Specifications

Pvt System Fastener Torques

Pvt System Overview

Clutching Chart

General Operation

Drive Clutch Operation

Driven Clutch Operation

Pvt Break-in (drive Belt / Clutches)

Maintenance / Inspection

Overheating /diagnosis

Pvt System Service

Pvt Sealing, Guard, And Duct Components

Pvt Disassembly

Pvtassembly

Drive Belt

Belt Removal

Belt Inspection

Belt Installation

Pvt Break-in (drive Belt / Clutches)

Clutch Alignment / Offset / Center Distance

Inspection

Adjustment

Drive Clutch Service

Drive Clutch Assembly View

Clutch Disassembly

Shift Weight Inspection

Spider Removal

Roller, Pin, And Thrust Washer Inspection

Button To Tower Clearance Inspection

Bearing Inspection

Clutch Inspection

Bushing Service

Clutch Assembly

Driven Clutch Service

Assembly View

Clutch Disassembly / Inspection

Clutch Assembly

Troubleshooting

Chapter 7 Final Drive

Special Tools

Torque Specifications

Wheel And Hub Torque Table

Front Hub/bearing

Hub Removal/inspection

Hubstrut Bearing Replacement

Hub Installation

Front Hub/wheel Exploded View

Front Drive Shaft

Removal

Installation

Front Gearcase / Centralized Hilliard

Centralized Hilliard Assembly View

All Wheel Drive Operation

Awd Diagnosis

Gearcase Removal

Gearcase Disassembly / Inspection

Gearcase Assembly

Gearcase Installation

Rear Bearing Carrier

Inspection

Removal

Disassembly

Assembly

Installation

Rear Drive Shaft

Removal

Installation

Drive Shaft Service

Drive Shaft / Cv Joint Handling Tips

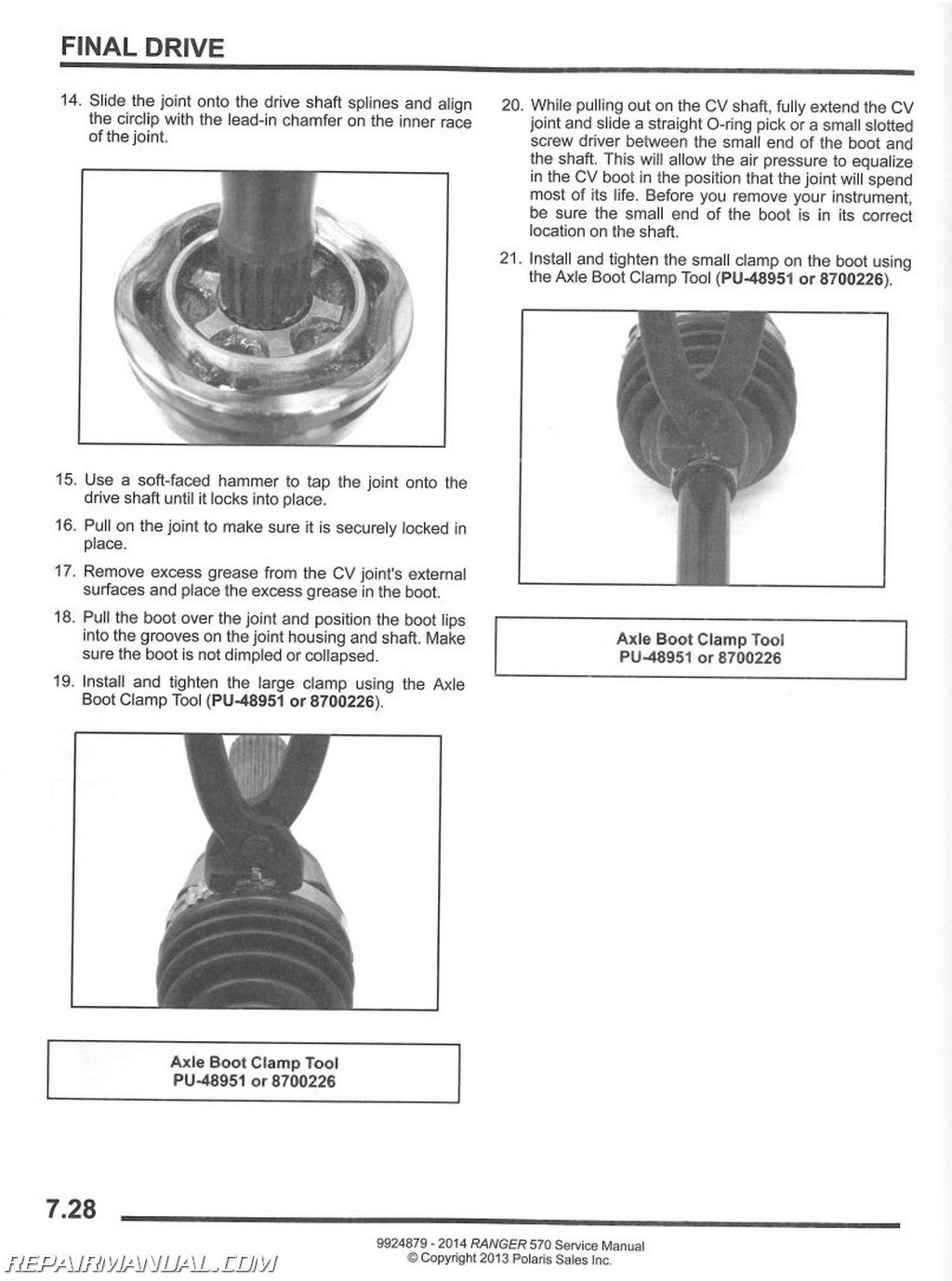

Outer Cv Joint / Boot Replacement

Inner Plunging Joint / Boot Replacement

Drive Shaft Assembly View

Propshaft U-joint Service

Removal / Installation

Front Propshaft Components

Removal / Installation (crew)

Support Bearing Replacement (crew)

Disassembly

Assembly

Chapter 8 Transmission

Specifications

Torque Specifications

Special Tools

Lubrication

Transmission Mounting And Torque Values

Shift Lever

Removal

Installation

Shift Cable

Inspection

Adjustment

Transmission Removal

Transmission Installation

Transmission Service

Differential Operation

Transmission Disassembly

Planetary Differential Disassembly

Planetary Differential Bushing Replacement

Planetary Differential Assembly

Gear / Shaft / Bearing Inspection

Snorkel Gear Backlash Procedure

Troubleshooting

Troubleshooting Checklist

Transmission

Transmission Assembly View

Chapter 9 Brakes

General Specifications

Torque Specifications

Special Tools

Brake System Notes

Brake System Service Notes

Brake Noise Troubleshooting

Hydraulic Brake System Operation

Brake System Assembly View

Ranger 570 Efi

Ranger 570 Efi Crew

Master Cylinder

Removal

Installation

Brake Pressure Switch

Foot Brake Pedal

Pedal Removal

Pedal Installation

Brake Procedures

Brake Bleeding / Fluid Change

Brake Burnishing Procedure

Front Brake Pads – 570 Efi

Pad Removal / Disassembly

Pad Inspection-570 Efi

Pad Assembly / Installation- 570 Efi

Pad Adjustment- 570 Efi

Front Caliper-570 Efi

Front Caliper Assembly View

Front Caliper Removal-570 Efi

Front Caliper Disassembly- 570 Efi

Front Caliper Inspection- 570 Efi

Front Caliper Assembly

Front Caliper Installation

Front Brake Pads – 570 Efi Crew

Pad Removal – 570 Efi Crew

Pad Inspection

Pad Assembly / Installation- 570 Efi Crew

Front Caliper – 570 Efi Crew

Front Caliper Assembly View

Front Caliper Removal- 570 Efi Crew

Front Caliper Disassembly- 570 Efi Crew

Front Caliper Inspection – 570 Efi Crew

Front Caliper Assembly- 570 Efi Crew

Front Caliper Installation – 570 Efi Crew

Front Brake Disc

Disc Inspection

Disc Removal / Replacement

Rear Brake Pad Service

Pad Removal

Pad Inspection

Rear Pad Installation

Rear Caliper

Caliper Assembly View

Caliper Removal

Rear Caliper Disassembly

Rear Caliper Inspection

Rear Caliper Assembly

Rear Caliper Installation

Rear Brake Disc

Disc Runout

Disc Inspection

Disc Removal / Replacement

Troubleshooting

Brakes Squeal / Poor Brake Performance

Pedal Vibration

Caliper Overheats (brakes Drag)

Brakes Lock

Chapter 10 Electrical

General Information

Special Tools

Electrical Service Notes

Battery Conductance Analyzer

Components Under Hood

Switches / Controls

Ignition / Headlight Switch

Awd / 2wd / Turf Switch

Differential Solenoid

Brake Pressure Switch

All Wheel Drive (awd) Coil

Operation Overview

Diagnosing System Failures

Vehicle Speed Sensor

Speed Sensor Location

Speed Sensor Testing

Instrument Cluster

Overview

Rider Information Display

Information Display Area

Diagnostic Mode

Instrument Cluster Pinouts

Instrument Cluster Removal

Instrument Cluster Installation

Headlights

Headlight Adjustment

Headlight Bulb Replacement

Headlight Housing Removal

Headlight Housing Installation

Tail Light / Brake Light

Led Lamp Replacement

Cooling System

Fan Control Circuit Operation

Fan Control Circuit Bypass Test

Cooling System Break-out Diagram

Ignition Coil

Operation Overview

Ignition Coiltests

Ignition Coil And Ht Lead Replacement

Relays

Operation

Fuses / Circuit Breaker

Operation

Charging System

Current Draw – Key Off

Charging System “break Even” Test

Charging System Alternator Tests

Charging System Testing Flow Chart

Battery Service

Battery Terminals/bolts

Battery Terminal Block

Battery Activation

Battery Inspection

Battery Removal / Installation

Conventional Battery Testing

Ocv – Open Circuit Voltage Test

Voltage Drop Test

Specific Gravity Test

Load Test

Charging Procedure

Off Season Storage

Starter System

Troubleshooting

Starter Drive

Starter Solenoid Bench Test

Starter Solenoid Operation

Starting System Testing Flow Chart